Debra Barclay of Ancora Press is a well-travelled printer who was inspired by the work of William Blake. She creates in her garage-turned-printshop and shares with us her lifelong printing mentors / friends she’s made along her print journey (as well as a favorite printing moment involving a Girl Scout Troop and a Vandercook).

WASHINGTON STATE PRINTER

My name is Debra Barclay, and I am a letterpress printer in Woodinville, WA. I live in Woodinville with my husband, 7-year-old daughter, 6-year-old son, 6-month-old Labradoodle, and two pretty lucky black cats, Uno and Tres. I’m a New Jersey transplant by way of Brooklyn, Virginia, Rhode Island, and Oregon. My favorite color at the moment is PMS 310 (light teal).

THE LURE OF LETTERPRESS

For my undergraduate degree, I attended Providence College in Rhode Island. My degree is in English Lit/Creative Writing and Printmaking. My senior year, I took a course on Romantic Literature and fell deeply in love with William Blake’s work. William Blake was a poet and printmaker who developed techniques to bring his poetry into a more visual realm. He combined text and image in a way that I had never seen up to that point. His poetry became visual as much as text-based, and he made it so the poem’s meaning was directly enhanced by the calligraphic lettering, colors he chose, and the overall design. In this way, he elevated the printing of information into a visual experience rather than just a transfer of data. At that point, I knew that I had to integrate my two passions: creative writing and printmaking.

After I graduated, I started looking into bookmaking classes. I found a school that had a very small but well equipped Book Arts Program. This was when I found the Oregon College of Art and Craft. I immediately enrolled in a few classes, packed my bags, and moved to Portland.

I really didn’t know what I was getting into, as far as letterpress printing goes. But there I was, learning to handset type and run a Vandercook under the tutelage of two women. Kathy Kuehn is a master printer at Pace Editions in NYC and Caryl Herfort, a letterpress printer from Texas who was there as the Artist in Residence. Many may know of Caryl from Roto Press (Rest in Peace, Caryl). Both of these women inspired me to experiment and play with the medium.

A CREATIVE ADVENTURE

As I continued to set the type for a short story I had written, my mind exploded. It was so crazy to be able to touch thoughts and ideas – letterforms as material objects with a history and life of their own just struck me on a very philosophical level. I then locked up my form in the school’s Vandercook Universal, and ended up a bit deflated. This was off course from my Blake path, as Blake didn’t use handset type in his work, possibly for this reason. Yes, typesetting is intimate, but once it gets on press and you print it with great craftsmanship, it does not show any of the depth or meaning that it had taken on when I handled it.

It was much more sterile and generic than I had envisioned my piece to be, given how emotionally and physically closer I had become to the words. This created some friction between me, the machine, and process. I moved my printing over to a hand rolled proof press, where I was determined to get the “hand of the maker” involved. Then, I hand-inked each pull, and ran the pages through one by one, skewing the registration so they would all be unique.

I actually still have a scar from this very first print run I did, as my thumb got caught in the cogs of the press as I was enthusiastically running pages through. The end result was a very artistic interpretation of letterpress! I created an art installation with the small edition of books I made with this experiment. I filled three walls of a gallery with the pages, and set up three of the spiral bound books on pedestals where viewers could flip-through the pages. The only requirement was that they wear white gloves, as is common practice when looking through fine press books.

However, the white gloves I provided were covered in black printers’ ink. So, the viewer/reader added and changed the book as they engaged with it – a visual representation of how we all change and alter language as we use it. It becomes a relationship where both parties – the ideas/text/ poetry and the reader/viewer – are changed through the interaction. We are all changed in sometimes undetectable ways by every interaction we have.

I then began to approach letterpress a bit differently, and started to think more about how words are laid out on the page, how the colors might interact with one another either through size, proximity, or overprint. I also started to notice the beautiful impression that letterpress machinery gives to the paper, making the text both a visual AND tactile experience for the viewer/reader.

A LETTERPRESS CONNECTION

Through this experience, I reconciled and truly fell in love with the exacting nature of letterpress machinery. It was through these experiments that I concluded that when I create, I am collaborating WITH the machine. With this finely engineered letterpress machinery, the ability to disseminate information in a way that allows for the content to be given the entire spotlight would now be possible. We are true partners. With that, my deep connection with letterpress continued to grow and develop into where it is today. I utilize the impeccable precision of the machinery to allow me to elevate letterforms, words, ideas, and everyday life moments into experiences with tactile beauty and time-tested craftsmanship.

HOME GROWN PRINTING

Ancora Letterpress is a custom letterpress print shop located about fifteen miles Northeast of downtown Seattle. We do custom designs working directly with clients as well as printing for graphic designers and other print shops who come to us with a pre-existing design of their own.

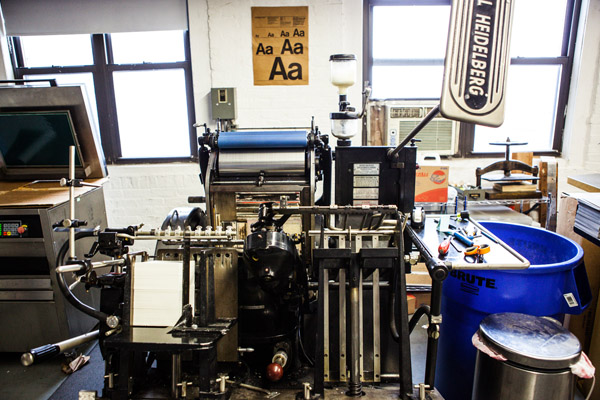

My shop feels like home. Mostly because it’s attached to it – in my garage! I have two 10×15 Heidelberg Windmills and an 8×12 Chandler and Price. I also have a photopolymer platemaker and a small guillotine paper cutter. My favorite thing about my shop is that I get to create there! Truly, it’s a dream come true. I also really like the commute.

WOODINVILLE WONDERS

Woodinville is a tourist destination, as we have over 100 tasting rooms, wineries, distilleries, and breweries within a stone’s throw from my shop. This can be dangerous, but it’s really quite convenient mostly. Chateau St Michelle is probably the largest winery in the area. They have concerts on the lawn in the summers and beautiful grounds to walk around and picnic on. In the summer, we can hear the music from our backyard, which is usually a good thing. We also have a really cool theatre production company in town called Teatro Zinzanni, which recently moved to Woodinville from Lower Queen Anne in Seattle. From their website: “Teatro ZinZanni…is a three-hour whirlwind of international cirque, comedy, and cabaret artists…”

I really love living here because it’s quiet and we have lots of space. Our house is nestled into trees at the end of a cul-de-sac, yet we are incredibly close to the city. Woodinville is described as “subrural” as it is somewhere between suburban and farmland. One of our neighbors has a horse grazing in her front lawn pretty regularly, and the one across from her has over a dozen chickens on his property. We have a growing Arts community thanks to the Woodinville Arts Alliance in town.

PRINTING MENTORS

Oh gosh! This is a hard question! So many people have helped me get to where I am today. Esther Smith and Dikko Faust of Purgatory Pie Press were my first inspirations, as they were my first apprenticeship out of school. Dikko’s skills as a printer always inspire me, and Esther’s vision and ability to draw inspiration in the everyday is joyous.

My former boss Scott Hill of Workhorse Press is a great mentor as I continue to build my business. He’s readily available to help me with any questions I have about presses, printing, or the business side of things. I’ll be forever grateful to him for taking me on as an employee and teaching me so much about the production side of letterpress. Scott is a printer by trade, with a very keen eye for how to bring a design to life on paper.

Jami Heinricher of Sherwood Press is my most recent mentor and inspiration. She taught me how to run a Heidelberg platen, and for that I am forever grateful. She helped me troubleshoot one of my presses’ weird quirky problems, and even helped me back out my stuck Windmill, after my press pulled 6 sheets of 236# Flurry Cotton paper! I admire her business model, and her tips and tricks have saved me hours of time. My friend George Feakes of Impressive Inkreations has been an incredible mentor, giving me both sage printing and business advice, insights on efficiency, and an amazing amount of support.

All of my local letterpress trade guys are all absolutely my savior. After running letterpress for 40 years a piece, they collectively know everything, and there’s nothing they can’t make run correctly with just a little bit of tape and 18 point card stock. They’re also really down to earth and easy to talk to, and I love hanging out with them.

My husband, while not a printer, has been an amazing source of inspiration and strength. He single handedly moved my C&P and first Windmill up from Portland and got them situated on the garage floor. He also gave up a large portion of his workspace to allow me to have my studio. We are now looking into building him a lovely shed in the backyard for his woodworking tools for when I get a few more pieces of equipment this coming year.

GROWING THE DREAM

My business works out to be part time at the moment. I bought some equipment in early 2018, and spent about 6 months getting myself up to speed on the equipment and its particular quirks and what-have-you. Technically I’ve only been available to the public for about 7 months. I do plan to continue to solicit work and build relationships with designers, as well as develop a personal line of designs that I can offer to clients. Full time is my goal. I want to generate enough consistent job and print work so that I can take on an employee. There’s only one thing better than being a letterpress printer, and that’s sharing the workload!

THE CREATIVE FLOW

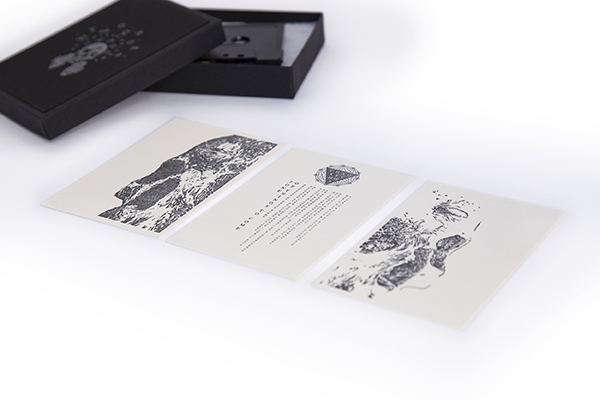

My process always begins by sitting down with the client and getting to know them a bit. I love getting to talk to people about their vision and translating that into a printed piece. I spend a fair amount of time gathering as much information as possible from the client. If it’s a wedding invitation, for example, I ask the bride to describe the ceremony and the type of event they’re going for. Is it modern, traditional, minimal, outdoor, etc? This narrows things down a bit. I get their wedding colors and match them to a PMS color that we all agree on pretty early on. I show them samples of my previous design work and see if anything stands out to them, either by way of technique (blind emboss, overprinting, etc) or if the tone of anything resonates with them.

At that point, I will begin a preliminary design. I find that this is really when the fun begins. It’s important to have a jumping off point, even if the design itself isn’t the final vision. It’s much easier for people to point out what they don’t like and for me to come up with alternatives to that, rather than envisioning something out of thin air. This has really worked well for me so far. I really enjoy the collaborative process during this stage of design.

PRINTING FEATS

I was the Arts Director of the Virginia Center for the Book from 2001-2003. While I was there, I helped run workshops and host events that built community involvement in the letterpress shop. I also created panel talks and art installations for Charlottesville’s annual Festival of the Book, which is a week-long event covering all aspects of books, from publishing, illustrating, designing, and reading. I also taught a class in the Art Department at the University of Virginia.

What I loved most about my time there was introducing the history and craft of letterpress to so many people in a variety of settings. One of my favorite moments was teaching an outreach program for a local Girl Scouts troop. I had the girls (who were all about 7 years old) run a pass through the Vandercook Universal. While I was in another room showing a group how to fold and slit the paper into a book, a girl came running out of the print shop in tears. Her mom asked her what was wrong, and she said through her sobs, “My print is over-inked!”

PRESS FAMILY

The very first presses I owned are my current ones – a 10×15 Heidelberg Windmill and an 8×12 Chandler and Price treadle that’s been converted with a motor. It’s funny that my first presses are both platens, since I learned to print on Cylinders. By the time I was ready to buy and had the space to have presses, Vandercooks were way out of my price range. Before this, I had always managed to access community print shops or presses belonging to friends.

BOXCAR’S ROLE

Boxcar has helped me in so many ways! Mainly, making resources readily available has been key. It’s a one-stop-shopping kind of place. They have given me the luxury of going slowly in building up my knowledge by offering a place to get it all done, and with such ease! The Boxcar Base has made life so much easier.

Before the Base, I was using magnesium plates. I found them to be much softer and more unpredictable, requiring more make ready due to being mounted to wood (not consistently flat on the bottom, and easily prone to warping). Being able to have predictable quality in my tools has allowed me to focus on perfecting my skills as a craftsman. The ability to buy paper, envelopes, order plates, and pick up a random thing I might need here or there (can of ink, roller gauge) has been fantastic. I can’t say enough good things about the Boxcar Press website flow. It is extremely user friendly, is quick and easy to navigate, and borders on foolproof!

I also love the How-To tutorials, which have increased my knowledge of my presses. Also, I cannot say enough great things about the staff. I have had random moments of panic where I’d forgotten to upload a small file for platemaking, only to call out an S.O.S. to Rebecca Miller, who swiftly and promptly put out the fire and saved the day! Working with Boxcar Press is like having a staff of knowledgeable and kind pre-press geniuses just an email away!

SHOP TIPS

Get the crop marks! This is something I don’t always do myself, and pretty much every time a two or three color cropless job goes to press, I spend twice as much time trying to get position. Even with one color jobs, I like crop marks once it gets to bindery. They seem like a luxury, but really they save you a bunch of time. And time is money, as well as a whole lotta frustration!

Spend the money! I’ve been there…I have tried to get away with a short cut, or making do without a particular tool or gadget (the Swing Away Lay Gauge comes to mind here). In the end, I end up spending way too much time having to figure out a “cheap” way to do something. Again, I’ve spent money, and potentially compromise the quality of the end result of the printed piece.

If you’re running a blind deboss on a stock that isn’t 100% cotton, or super plush, you can achieve a similar effect by adding a small amount of color that matches the paper stock with a ton of transparent white. Or, if you’re running a bright white sheet, opaque white right out of the can will do the trick.

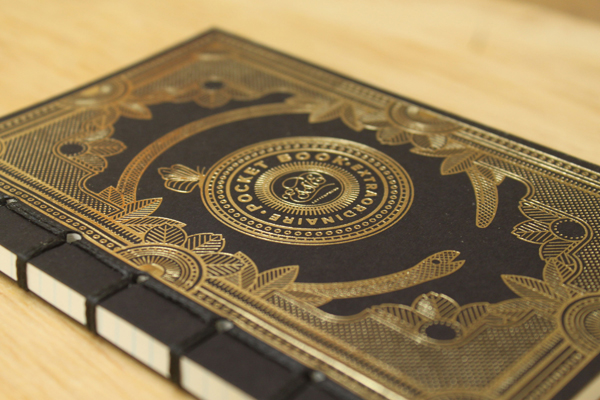

I’ve also added a touch of yellow to gold ink in order to give it the punch it needs to stand out on an absorbent stock.

PRINTING ADVICE

Letterpress is a lot of troubleshooting and problem-solving. Isolate problems, ask for help from fellow printers that you know, or reach out online. One of the things I love about letterpress is how knowledgeable and helpful the community of printers is.

Also, a motto I like – Stay modest, do good work, enjoy life outside the shop.

WHAT’S COMING NEXT

For the upcoming year, I will continue to grow my clientele. I also plan to add equipment so that I can add foil and emboss to my skill set. Currently, I am creating a design line, more of my own greeting cards, and some stock offerings that can be semi customized, like monogrammed note card sets and Holiday cards. I also hope to learn to paddle board!

(photography courtesy of

(photography courtesy of  (photography courtesy of

(photography courtesy of

(Top Notch box designed by

(Top Notch box designed by

(Aristocrat box designed by

(Aristocrat box designed by