Typebee studio’s very own Breanna White’s extraordinary printing journey started with a curious stumble over a classified for a letterpress internship. After the pull of the trip, the instantaneous (and quite insatiable) hook set in. Fast forward a few years later and Breanna is bridging the gap between old generation printing and new printing techniques at her cozy shop. With a small pile of chocolate at the ready (as she’s unabashedly a chocoholic), she sat down with us between ink runs to talk about her escapades for printing with DOMA coffee, the joy of working with her hands, and her inspirational (and aspiring printer) daughter, Jaedah.

CREATIVE CHOCOHOLIC PRINTER In a nutshell, I’m a biodynamic gardener, book nerd who loves chocolate, not coffee… I know, designer’s sin, guess that’s why I’m a printmaker for a coffee company? Wait, how’d that happen?

LUCKY WITH LETTERPRESS It all began as a child, being handed the assembly-required gifts at holidays. I was attracted to the process of building. Starting with a myriad of unfamiliar objects, working through the technical illustrations labyrinth to arrive at a complete, usable item. One could imagine clicking a mouse eight hours a day wasn’t exactly filling my cup. So when I was tasked to find an internship, I began researching the tail end of design. Printing. I stumbled across a listing for a letterpress intern at Steel Petal Press reading ‘hand skills required’. That’s me!! Embarrassed to admit, I didn’t even know what letterpress printing was at the time, but I remember the very moment when I pulled the trip, making my first impression. I was hooked. Not just the impression, the whole of the process. There is something magical about process, the unfolding of a project over time. Since we are by design process-oriented beings, process-oriented tasks help us connect at a deeper level.

With that, I found myself traveling to Webster, NY to purchase my first letterpress. A C&P Pilot from Ray Czapkowski at Dock 2 Letterpress. After meeting Ray, I realized his generation of printers understood the process from a practical and mechanical point of view. Which is necessary in the modern, because who are you going to call when the drive wheel from the 1924 New Style C&P decides to fly off at random, rolling towards your boss innocently sitting in the corner? Or when the original wood spool cracks during a lecture to NIC Students causing the belt to slip? It’s helpful to understand how the equipment functions so you can identify and fix malfunctions. The drive wheel was stripped, so I tapped new holes. The spool no longer had an evenly arched surface causing the belt to ride the higher route jamming it against the motor, so I evened it out with duct tape for the sake of continuing the lecture until it could be repaired. These are lessons learned from people like Ray and Ed Regan who taught me the historical and technical aspects of letterpress. There’s a lost generation of printing knowledge, it’s important to bridge that gap, and ask questions because knowing the limitations of the output gives way for good input. Start with output and work backwards.

COZY PRINT SHOP It’s 400 square feet of pure bliss. If there were a shower, I’d highly consider moving in.

DESIGNED TO PRINT My initial training is in Visual Communications with a BFA from the Illinois Institute of Art – Chicago along with typographic studies from HGK in Basel, Switzerland. So I wear both hats but I enjoy printing most. And the fact that I get to wear an apron to work is pretty appealing. I’ve been fortunate to work with a diverse group of clients and designers and enjoy the collective efforts. Having had prior experience with the design process does give the ability to communicate effectively with clients and designers alike.

THE CREATIVE PROCESS Research. Research. Research. Then long walks to visualize the final idea and from there work backwards taking into consideration the output of the design before creating a roadmap, also known as the lost art of sketching. Coupled with many chocolate intermissions. If I find myself spinning the wheel, I take another walk to get the creative juices flowing. Once I have a tight comp, I’ll bring it in digitally. My least favorite part of the process…

FULL TIME PRINTER I letterpress full time in parts for the last two years and have been printing for five. I own my business, Typebee Letterpress Printshop and also subcontract for companies like DOMA Coffee Roasting Co.

COFFEE TIME Finest coffee you’ll ever taste. It’s of an unfortunate irony that I cannot drink it. Here’s the story:

As a recent arrival from Chicago, I soon understood searching for studio space in Spokane, WA would become a Quest of Epic Proportions. And as the universe would have it, a trail of crumbs led me to the front door of DOMA Coffee Roasting Co. in Post Falls, ID. I have had the fortune to work unique jobs in my lifetime, cleaning a coal mine for one but in no way did I know solicitation for letterpress restoration would be one of ’em.

Following my 30-second elevator pitch to Mindy, Jack-of-all-DOMA, I awkwardly lingered in the front entrance. I’d like to believe before words were ever exchanged between Rebecca, owner of DOMA, and I that we knew something magical was already in the making. After The Wonderful World of DOMA tour, we came upon our last stop, The Press. If you have ever felt motionless in a point of time whilst all else carries on around you… The Press was that point. And some employees would admit, a hindrance between point A and point B.

If you can imagine a 5’3” lady weighing approximately 120 lbs. soaking wet wearing denim coveralls too many sizes too big, with nitrile gloves and a half face ventilator mask… well, there I was with wire brush and mineral spirits hand scrubbing a 2,500lb. cast iron beast of a lady clad with God only knows what. I think too often we perceive the old as something to avoid or something to replace. Letterpress printing is more than ink on gorgeous paper; the process represents a historical pivot, one of equal corporative between craftsman and machine.

After the letterpress was restored, well someone needed to operate it. For a time I flew back and forth between Chicago and Idaho to fulfill orders. It was in November of 2014, DOMA was having an open house for the Winter Wonderland coffee bags and Lee from Letterpress USA stopped by asking a lot of questions. At first I thought she was interested in the process but later realized I was being tested on my expertise. Less than ten minutes of her departure I received a phone call asking if I’d like to work for Letterpress USA. I said yes without thinking, hung up the phone and realized that I lived in Chicago!! Ha. So naturally I went home and packed the car and then headed west. I currently work part-time for Letterpress USA as a journey(wo)man learning Die Cutting, Perforating, Scoring and Foil Stamping.

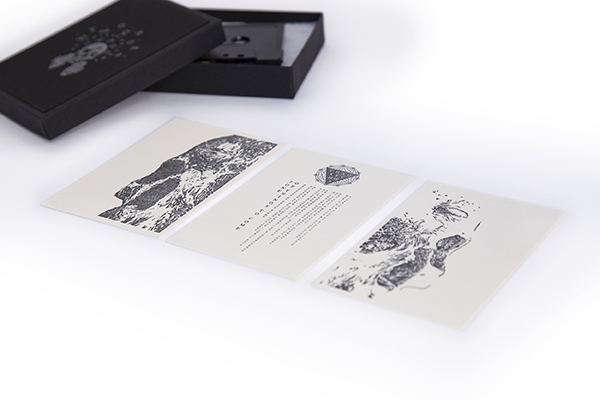

On the side, I offer private lessons and lecture about the history of letterpress & the process of printing. Also just began a joint Greeting Cards venture: CardCo Lab is a collaborative letterpress project managed by myself, printmaker Bee, and creative writer Michal Bennett. Our purpose is to craft exquisite and one-of-a-kind letterpress greeting cards that connect brilliant artists, creative minds, and judicious consumers. Each card that we create is printed as a limited edition run and is only available until sold out. Then it’s on to the next beloved project.

PRINTING FEATS The first one that comes to mind, is restoring DOMA’s New Style C&P. It had sat for 30+ years and needed some TLC. When we fired Er’ up for the first time, Rebecca, owner of DOMA, and I just looked at each other in a state of ‘is this really happening?!’. Another was when I finally mastered printing on bag gussets without a break in the ink. The Addy Award was a proud moment too.

PRESS HISTORY My first letterpress was a C&P Pilot from Webster, NY. In a few weeks Bootup (boo-dup), will be having a new home in San Jose, California. Er’ is a well-traveled press: New York to Chicago to Post Falls to San Jose. Tear tear, Er’ will be missed. Other presses in the shop: Pulowech (pul-lah-wetch) a New Style 12 x 18 C&P, Nukumi (noo-goomee) an Old Style 10 x 15 C&P and hopefully coming soon Nakuset (nah-goo-set) a Heidi 10 x 15 Windmill from Seattle. Much needed for my poor back.

BOXCAR’S ROLE Letterpress in the modern would not exist at its current capacity without Boxcar Press. This is where technology and old world methods meet. As I’ve said before, letterpress is a process in a non-process oriented world. People want to push buttons and enjoy instantaneous gratification. If it weren’t for platemaking services like Boxcar, I’m not sure how practical letterpress would be from a turn-around standpoint. Personally, Boxcar has helped me from the very beginning from understanding what base/plates to use, troubleshooting and same-day turn around when you’ve overlooked placing the headline in your artwork. Oops. As Michael at Letterpress USA says, “Print Happens.” Thank you Cathy, Rebecca and the Boxcar team for all you do!! And I have to say, I think it’s important to create and foster relationships within the printing community. It’s exciting to see people joining the craft, which keeps us moving forward. Boxcar has always been that pillar in the letterpress community.

SHOP TIPS Never count anyone out, by that I mean we all have something to teach and something to learn. Ed is a great example. He was considered a mere mover of presses. After striking up a conversation he became one of my greatest mentors. And has a treasure box of information and history one couldn’t believe. One of my favorite stories of his is about simultaneously running three Heidi Windmills as a youth. I remember being in awe, now I can do the same. Picture your vision, and enjoy the process of getting there.

WHAT’S NEXT I’m working towards offering everything under one roof; design, letterpress, packaging and finishing. I’ve spent the last seven years learning each part of the process in depth and would like 2017 to become a year of transition from being a solo printer to having multiple people of their respective fields working together with Typebee. Press on.

LAST THOUGHTS The most important piece to all of this, are my daughter Jaedah and her sidekick MoMo, a rainbow stuffed sock monkey. They’ve always been at my side and eager to spin every flywheel we come across. She’s my little inspiration and aspiring printer.

Immensely huge round of thanks out to Breanna of Typebee for the unique glimpse into her exceptionally awesome printing realm!