If you’re a letterpress printer in the 21st century, chances are you want to work directly from your design files to polymer plates. But how to mount your plates to a type-high surface? Thousands of letterpress shops, fine presses and universities across the globe have fallen in love with the Boxcar Base system. Paired with plastic-backed polymer, our base creates a stable, easy to use type-high surface for cylinder or platen letterpresses. In fact, our system will hold your printing plates better than any other letterpress base on the market, guaranteed. We also provide life-long printing help and technical support to the letterpress printers who use our bases—just email or call 315-473-0930 x 12, when you’re on press and encounter a problem.

-

10×15 Chase Starter Pack

$390.00 Add to cart -

8×12 Chase Starter Pack

$296.00 Add to cart -

6.5 x 10 Pilot Starter Pack

$285.50 Add to cart -

6×9 Chase Size Starter Pack

$273.00 Add to cart -

5×8 Chase Starter Pack

$264.00 Add to cart -

Vandercook Starter Pack

$676.00 Read more -

Heidelberg Windmill starter pack

$390.00 Add to cart -

Boxcar Base Scraps, Specialty base sizes for letterpress

$13.00 – $22.00 Select options -

Deep Relief Boxcar Base

$175.00 – $325.00 Select options -

Standard Boxcar Base

$190.00 – $1,300.00 Select options

How the Boxcar Base works.

Our bases are precisely engineered from cast aluminum, ground to perfection, then anodized with a grid for easy registration, providing an ideal foundation for letterpress printing. The Boxcar Base is guaranteed to within 0.001″ in thickness, parallel, and flatness: this ensures you’ll be printing on the flattest surface possible—flatter than many press beds in fact. Our bases are made in the U.S. from the highest quality American tooling plate. We manufacture all our bases with the same craftsmanship you put into your letterpress printing.

The Boxcar Base system consists of:

- a precision ground and gridded Boxcar Base, which is reusable and locks up in your press’s chase or bed

- double-sided adhesive

- plastic backed photopolymer plates, which are reusable (and recyclable)

The double-sided adhesive adheres to our plastic-backed plates, turning these plates into high-tech stickers with a super-strong hold. After you push the plastic-backed plates to your base, the plate moves only when you want it to: our adhesive & plates pulls up from the base easily when lifted vertically, but resist the horizontal shearing of the rollers and press cylinder.

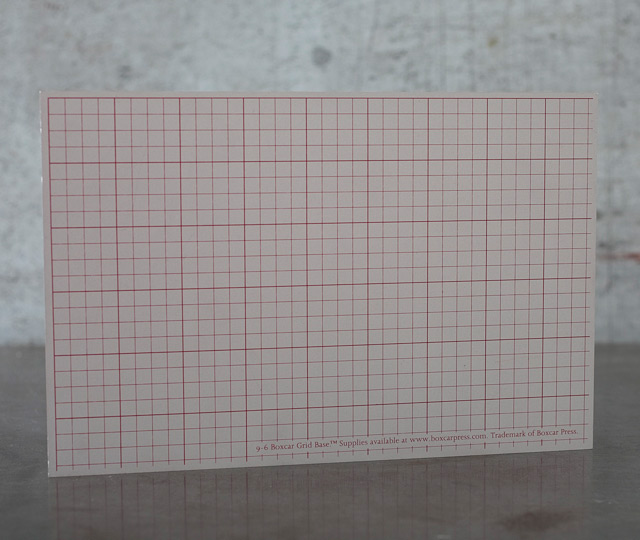

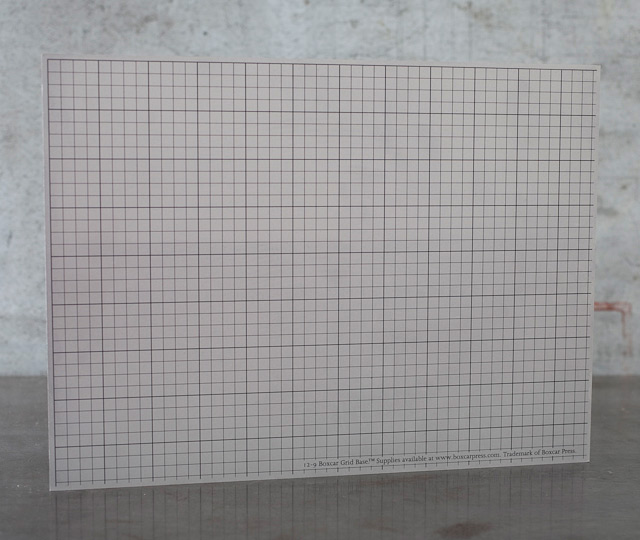

To make registration easier, we’ve anodized a grid onto our bases of .25″ lines: black lines for the Standard Base, red lines for the Deep Relief Base. Because plastic-backed plates are transparent, you’ll be able to see the grid through your plates for convenient positioning on press. To align your plates to your base, take a horizontal or vertical element in your plate (this could be your registration marks, or a horizontal line in your artwork) and simply line it up to the grid. The base’s anodizing also protects the metal surface from scratches and wear with a permanent coating that’s harder than a sapphire.

The Boxcar Base’s polymer plates are easy to cut–just trim with scissors. If you keep your adhesive clean, you’ll be able to reuse it when reprinting your plate (though it’s easy enough to put new adhesive on an old plate).

We manufacture bases in a lot of sizes for a lot of presses. Find the recommended size for your press! Check out our Boxcar Base scraps too—perhaps we have just the size you need already. Ask us about custom cutting a base down to the size you want or for multiple base pieces from a larger one. There is no charge for the cutting–just give us an extra week to get it done. What is seen online for base scraps is what there is – availability is limited.

Deep Relief versus the Standard base in a nutshell

Choose the Deep Relief Boxcar Base

- if you’re a new printer who has a platen press (other than a Windmill) – a C&P, a pearl, etc.

Why would we say this: The Deep Relief Base pairs with thicker polymer plates (KF152), which helps keep the inking rollers from inking the base and plate backing. Accurate roller settings are still important, but these Deep Relief Bases make printing on a platen press easier–it’s essentially a more forgiving base for those printers using a C&P or other platen press with roller and ink disk systems. Note that the Deep Relief’s KF152 plates are slightly more expensive than the Standard Base’s 94FL / KF95 plates.

Choose the Standard Boxcar Base

- if you have a Heidelberg Windmill or a cylinder press (like a Vandercook or Heidelberg Cylinder)

- or if you have a platen press (other than a Windmill) but you’re an experienced printer who have mastered roller height adjustments—you’ll just need to make sure your inking rollers are set perfectly with the help of a roller gauge.

Why would we say this? The Standard Base’s plates (94FL / KF95) are less expensive than the Deep Relief’s KF152 plates. The plates used with the Standard Base are also slightly thinner with varying hardnesses between 62 and 75 so they compress less as you push into soft paper. All our plates give a nice bite into tree-free papers. Over here at Boxcar Press, we use the Standard Base (with the Jet 94 Clear plates) on all the presses in our shop. Essentially, use the Standard Boxcar Base if your press, your roller adjustment skills, and your printing experience allow it.

Two other cool things about our base.

- Purchase one of our bases, and we’ll help you out until you’re printing well. We want to make sure you love using our base as much as we do. If you encounter any difficulties with our system, on press or off, just email us or give us a call, and we’ll troubleshoot your printing with you until you’re happy.

- We guarantee that your Boxcar Base will work for you. If you’re unhappy for any reason, call us! We’ll guide you through different ways of adjusting your press to receive optimum printing from your plates and base. If our base still can’t make you happy, contact us for a return authorization number, and then return the base to us for a refund.

How are other printing methods (like magnetic bases, lead type, and magnesium plates) different from the Boxcar Base?

Find out the differences between

- a magnetic base and the Boxcar Base

- magnesium plates and the Boxcar Base

- lead type and the Boxcar Base