The sleep machine is running, unaware it is being watched. Long out of production, this Heidelberg 10 x 15 windmill letterpress still runs smoothly & precisely with the loving care it has been given over the decades. If you listen closely, you can hear it breathing & purring as ink is pressed to downy white cotton paper.

Tag Archives: Boxcar base/plates in action

Ink Blooming

One of my favorite parts of printing is watching fresh ink bloom on the rollers. Royal blue comes up nicely. Yes, to the printers out there, I did tighten up the rider roller. Laypersons that’s the silver one on top that carries extra ink and didn’t ink up like everything else.

Joe Knows

Say hi to some of our pressmen!

Boxcar Talk With Kent Aldrich

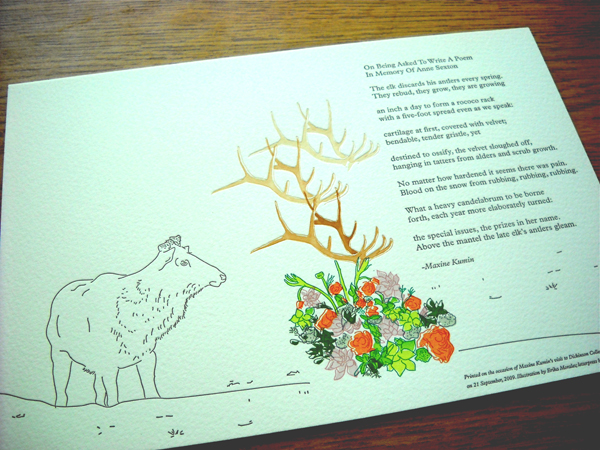

Kent Aldrich is everywhere: from falling in love with World War II posters, cutting his teeth on metal type, and standing quite still as the elusive (and brilliant, we might add) man behind Nomadic Press. He refuses to be defined by printing parameters, rather, he deftly commands them in his letterpress work. Read on to find out more on the musings of this passionate printer.

THE NOMADIC PRINTER I was born in 1964 and I am still living today. I was fascinated with type forms as a young child and designed a couple of fonts (leaning heavily toward an art deco style) when I was in second grade. I have lived most of my life in the Twin Cities of Minneapolis and St. Paul. I have been married for 22 years to the same woman, Emily, with whom I have 2 children. I ride a scooter with 46 rearview mirrors on it, I shoot a decent game of pool, and I like a beer with a strong hop flavor.

TEXT, FUN & ROCK ‘N ROLL When I was fourteen years old, I had fallen in love with poster art: Rock posters, French night club advertisements, WW2 recruiting posters. Anything intended to be tacked upon a telephone pole or hung up on a wall. So, I stole a composition stick (and the first line of a dead form) from a local jobbing shop and rode a hound down the Mississippi river to Winona. Once there, caught in the yellowing teeth of a full moon midnight, I sought out a lonely gravel crossroads where I met with the Devil and sold my soul for to print.

From there it was a series of graphic arts classes in high school,wooden renaissance festival presses, and a 3 year run-in with Coffee House Press and (the then just established) Minnesota Center for Book Arts. All of which conspired to push me into starting my own print shop, The Nomadic Press.

MAJESTIC MINNESOTA The building housing The Nomadic Press was built in 1914. The brick, from which it was built, was fired in a kiln a mile and a half away on a bluff overlooking the Mississippi River. It was originally a Mom & Pop grocery store and sat at the end of a street car line. The owners lived above the store, as did my wife and I for the first 7 years of our owning the place. With maple floors and woodwork and big, west facing windows, the interior of The Nomadic Press has been laid out following suggestions published in Mechanick Exercises on the Whole Art of Printing (1684) and has been outfitted in the style of a jobbing shop from the 1930s.

Nomadic’s press stable includes: two hand fed Chandler and Price old style platen presses (10 by 15 and 8 by 12), an automatic feed Kluge (12 by 18), a Vandercook Universal I (with a power carriage, adjustable bed and take-up tapes), the Pearl (more on that press later), and a spattering of table-top hobby presses.

PRINTING LEGACIES Al Schwerdt showed me how to print clean work using inking balls and a solid oak lever press and taught me the satisfying importance of the ethical and respectful treatment of both clients and vendors.

Allan Kornblum, who founded Coffee House Press, and spent years patiently teaching me the craft of letter-spacing and the fine art of keeping my hands out of the hungry jaws of a roaring platen press.

Will Powers, who made it plain that a printin’ man is a man well satisfied.

And Joseph Moxon, who said it best when he said; “As he set this stick of letter, so he sets on till his page is out”.

THE DAILY GRIND When I was first learning to print I slept on the floor of the print shop with my head on the feet of the press. Every morning I drink a hot cup of Van Son rubber base ink. Black. I have a ream of 80 pound text for lunch and bowl of 24 point em quads for dinner. My children were conceived in a room directly above my C&P 10 x 15. Too much information? Probably. But, heck yes, I print full time! For the last 26 years I’ve printed full time, and I plan on dying with my stick in my hand (that’s composition stick).

DESIGNED FOR PRINT Letterpress printing is, by its nature, a process who’s accessibility and immediacy demands a skillful confluence of art and craft. It is not enough to know how the press is best run, nor is it at all well enough to fix a pretty picture in one’s mind. Rather, a holistic knowledge of afore and after is called for.

ALL THAT’S FIT TO PRINT When I am designing my own work, and am using movable metal type, I like to set an element and print it. Then I set the next element and print that. And so on ’till the work is finished. It is a process that often finds me printed into a corner. And it is always a thrill to find the word, or type face, or ornament or color which, when laid down with the rest, finally pulls it all together and lets me walk out clean. When designing for clients, it all must be planned out beforehand though. Then I set great store in knowing what kinds of printed pieces they do /not/ like. Here be monsters.

PRINTER’S PARADISE The Nomadic Press is run out of a brick building which was built in 1914. Last year, Emily and I paid off the mortgage, and we now own the building outright. I have done printing for Nelson Mandela and Vaclav Havel, and I have produced work for the King of Norway and the Palace at Versailles.

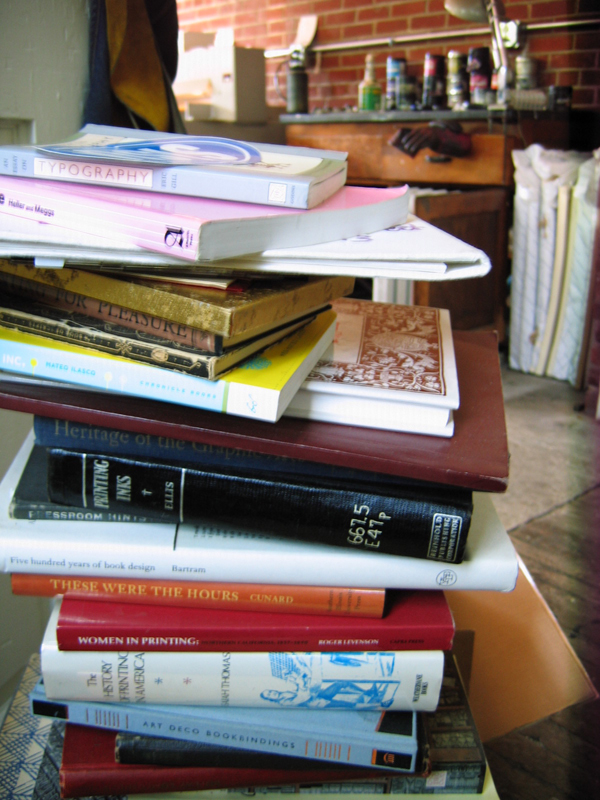

BOXCAR’S ROLE Having begun my letterpress printing career more than a quarter of a century ago, and having cut my teeth on metal type, I have worked with all manner of plates and blocks: Linoleum and end grain maple, electro-plate and zinc, copper, lead and magnesium. All have graced chase and bed here at The Nomadic Press. And they have all served adequately well.

But the photopolymer printing plates that Boxcar has developed, and now sells, are a printer’s dream come true. They are quick and clean and precise and they provide a seamless interface between my state-of-the-art presses (circa 1890s) and the cutting edge graphic design technology of today. And they impart, into soft papers and onto hard, a crisp impression that does a printer proud. It is hard to imagine the occurrence of the 21st century letterpress revival without Boxcar steaming into the station and hauling most of the freight.

PRESS HISTORY You always remember your first press. As is so often the case, I simply mentioned that I was looking for a press to someone who had talked to a person who knew of a clamshell platen that somebody had somewhere. So, for fifty bucks, I bought a 7 x 11 inch Pearl press, a Paragon guillotine cutter and a cabinet of type. And I had to get them out of a basement by the end of the week. I still print with her (and oh, the sweetness of her kiss!).

SHOP TIPS Know in which direction the grain of your paper runs, and be very kind to your register pins.

WHAT’S NEXT Big picture; I am working to build another 21% growth in gross over the previous year. Small picture; I hope to be able to print something using Pantone Mixing System number 332 (uncoated).

Huge thanks to Kent for letting us get a sneak peek at the fabulous Nomadic Press!

Photographs provided by Kelsey Johnson and Andrew Hine

Busting out Bellybands

Jake is setting up the Vandercook to do some bellybands in lovely & large pewter polkadots.

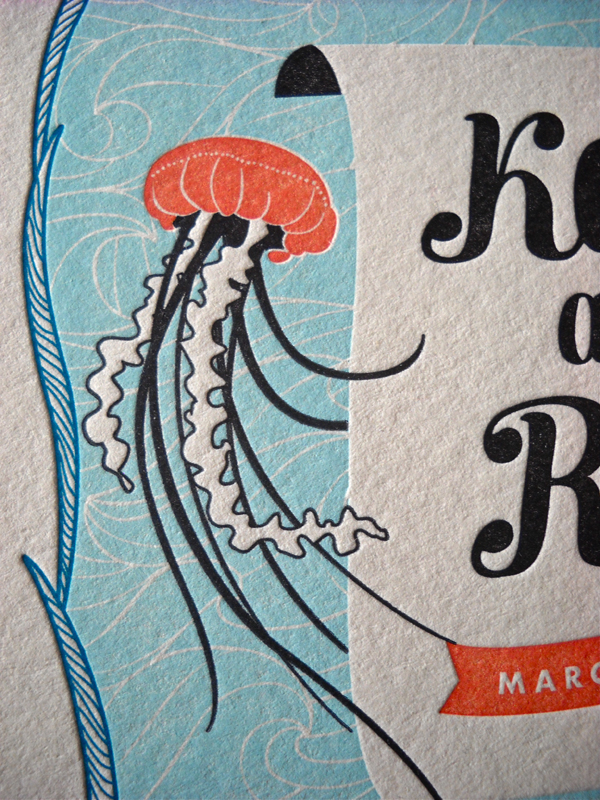

Boxcar Talk With Kseniya Thomas

Six years working at a cozy letterpress shop– especially one that’s basking in sunny Pennsylvania — is going to create some nifty pieces and fine design. Or at least it will inspire an entire weekend devoted to the art of the letterpress, ala The Ladies of Letterpress conference. After working in Mainz, Germany for a half-year of traditional typesetting and printing before opening up shop (Thoma-Printers), Kseniya Thomas’s love of letterpress is founded on skill, encouragement, and a big scoop of care. Here, Kseniya weighs in on the letterpress community, printing adventures, and her love of miniatures.

LIVE, WORK & DIRECT I’m Kseniya Thomas, and I’m a recovering English major from Salt Lake City. I currently live and work in Pennsylvania, where I’ve been happy to call myself a letterpress printer since 2005. I own Thomas-Printers, a commercial letterpress shop, and, with Jessica White of Heroes and Criminals Press, am the co-director of Ladies of Letterpress. I’m crazy for the Tour de France, old houses, running, newspapers, and anything in miniature.

INSPIRED BY GUTENBERG After graduating from college, I had a fellowship to study and work in Germany for a year. A friend and I happened to go to Mainz one weekend (I loved movable type, but didn’t yet fully understand the implications!), where the Gutenberg Museum has a working letterpress print shop. I wrote and asked if they accepted interns, and they did, so I moved to Mainz. I worked there for six months, and learned how to set type and print from guys who had spent their whole careers in print shops as pressmen, stonemen, or compositors before offset printing edged them out.

It was great: the shop has hundreds of lead typefaces, and I could print whatever I wanted. I also once printed a birth announcement for a princess, which was neat. I had no idea at the time that I had found my calling in life; even after I returned to the U.S., and realized that letterpress was happening here, I still only knew the basics of the history of printing and the craft of letterpress. And I knew nothing about running a small business!

A SUNNY SHOP My shop is located in the corner of an old shoe factory, with a room for shipping, receiving, and communications (ie, email), and a pressroom with a loading dock. The best thing about it is the tall, south-facing windows; in the summer, the only light I need is my color-correct lamp. I don’t think I’ll ever have another shop so sunny. It’s not decorated per se, except in a paper-stack, envelope-inventory, sample-shelf sort of way. It’s more workshop than showroom, so I don’t worry about hanging too much on the walls.

CARE FOR YOUR BUSINESS My best business advice is to learn to love your customers like family. They need care and attention just like family, and are the single thing, even more than hard work, that will keep you in business. Also, if you’re just starting out, don’t get caught up in playing catch-up with more established printers; there is no right way or one way to get where you want in this business, so your way is as likely to succeed as anyone else’s.

DESIGNED FOR PRINT I’m a printer who can design in a pinch, but I work with several great designers who can handle it when things get complicated. It’s nice being able to have designers who are familiar enough with the letterpress process that the finished product is going to print up great.

THE DAILY GRIND I do print full time. And when I’m not printing, I’m doing the 1000 other things a small business owner must do. Chief among them: worry, answer emails, write estimates, talk with clients, and a host of other pre-press, post-press, finishing, and ordering duties. Every day is different and yet comfortably similar, and now that I’ve been doing it full time for six years or so, I wouldn’t have it any other way.

ADVANCING A COMMUNITY I’m proud that Thomas-Printers is surviving the economy and doing well. Most recently, I’m proud of Jessica and I for organizing the best conference I’ve ever attended. The Ladies of Letterpress conference was such a happy, fun letterpress-fest, and it was thrilling to see so many ardent letterpress supporters and printers in one place.

It was also encouraging to see that letterpress is still going strong, new people are starting to print every day, and people are loving what we make more than ever. I cannot wait for a repeat next year!

BOXCAR’S ROLE It’s not an exaggeration to say that, without Boxcar, neither Thomas-Printers nor Ladies of Letterpress would exist. I got my start setting type, but setting type for every client isn’t a good business model for me. So the Boxcar Base is as important and valuable a tool as the press itself. Aside from the base and plates, Boxcar is the friendliest, fastest, nicest supplier I work with; the positive attitude and enthusiasm of the owners and staff has in turn contributed to the good-feeling and camaraderie in the letterpress community.

PRESS HISTORY My first press was a 12×18 Chandler & Price that I bought from Bill Welliver through the Letpres listserv. I used it for everything, large and small, for almost three years, until I bought a 10×15 C&P that allegedly only had had one owner and then sat in storage for 30 years. I also have a treadle-powered 8×12, which is handy when the power goes out. C&Ps are great presses, simple to use and relatively readily available, and are capable of a lot of fine work.

WHAT’S NEXT Ladies of Letterpress will be at the 2012 National Stationery Show for a third year with a new, super, wonderful, talented group of printers. And the second-annual LOLP conference is happening again-stay tuned for more details.

We’d like to give bigs thanks to Kseniya for taking the time to give us the scoop on Thomas Printers!

We have weird stuff in our drawers!

Wrenches, suckers, hoses, & gauge pins oh my!

Paper Feeding

See how far the top of the paper stack is away from the holes and springy fingers? That’s a good space for smooth sheet feeding. Keep the stack rising at this constant rate depending on paper thickness, amount of air blast, angle of suckers and where air blast fluffs up the stack and you’re in business as a smooth operator.

Boxcar Talk With Jackie Robinson

Jackie Robinson is wonderful letterpress gal creating beautiful designs with 42 Pressed. Armed with typographical know-how and an acute attention to detail, Robinson’s work has been hit after hit with her letterpress customers. Read on to get the full scoop on this extraordinary lady of letterpress!

Can you tell us a little about yourself?

My name is Jackie Robinson and I am the owner/creative director of 42 Pressed. I live in St. Augustine, Florida with my husband, two dogs and brand new baby girl, Riley Magnolia Robinson. We also spend a lot of our time at our other house in Charleston, South Carolina, where my family lives and hope to get back to one day!

How did you first get involved in letterpress?

I went to grad school at a small portfolio school called the Creative Circus. I studied graphic design there and had a professor, Berwyn Hung, who was a big letterpress printer. It wasn’t until after I graduated that I really got into it, and he taught me everything that I know. After I started messing around with designing stationery and doing a few wedding suites for friends and for my own wedding, it just kind of clicked that this was what I wanted to do.

Tell us a little about your design process.

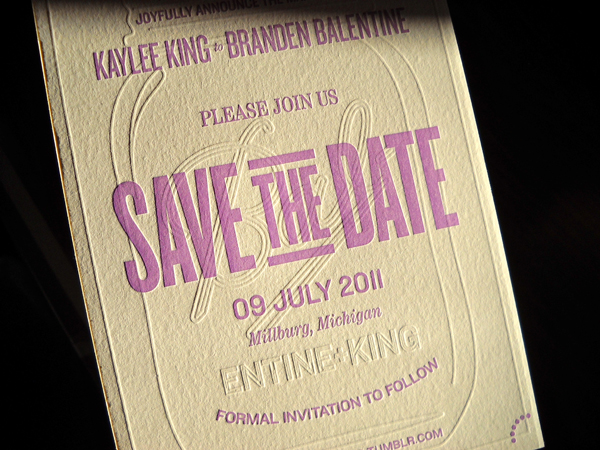

I really like to think out of the box and be different. My design style is heavily based on typography (I love type) so you will see a lot of that throughout my lines. When I am designing for a wedding, I really try and hit all different styles and imagine myself a bride again who wears Jcrew, one who is a hippie, one who is classic and chic, etc. and I pretty much establish a style that seems to fit every bride in their own right. My line appeals to pretty much everyone who likes to be a bit different and stray from the ordinary. I love using different materials and textures; I love to pair rough with delicate. I really just like to play with the unexpected.

When did you start printing?

42 Pressed has been operating since November of 2009.

What are some accomplishments you are proud of?

I am proud and fortunate to have gotten lots of great press: we’ve been featured on Martha Stewart, countless amazing blogs, and recently landed on the cover of Stationery Trends. We also attended our first National Stationery Show in May of 2010 and landed in 30 stores nationwide as a result.

How has Boxcar Press helped you with your business and printing?

Honestly, so so much! I was using Magnesium that was mounted on wood for my plates for a long time. I had issues with warping, with the magnesium pulling off the wood etc. Yes, it’s true that the mag mounted on wood is what real letterpress is all about, but the photopolymer plates have given me so much less of a headache. I know what to expect from them every time, and it’s a great product that I can rely on to get the job done well without the added stress that letterpress sometimes brings. If you are a letterpress printer, you know so many things can go wrong, so it is nice to eliminate a problem all together, and Boxcar plates help me do that.

What was your very first press? Was it love at first sight?

My first press was a Vandercook 15-21 and is still my only press. It has an adjustable bed which I love, it would be hard to bring on another press since I am just so in love with the one I have currently.

Describe your print shop. Any cool or nifty things about it?

It is fun, lots of color, lots of sunshine pouring in, dogs lounging around, music is always blasting. It’s definitely an inspiring space to be in.

Any neat tricks or advice you can share?

Never let a letterpress defeat you or frustrate you, always try and solve the puzzle and win.

What plans do you have for 2012 that you’d like to share?

Well, we just had our first baby!! So things have been insane around here, but I am starting to get back into gear again and think about the 2012 stationery show that we plan on attending. There will be a lot more ready made things, and I am also planning on designing and releasing new products once a month (ready made items) to keep us fresh and new with limited quantities. Stuff will go fast and remain relevant and in the now!

Many thanks to Jackie for letting us take a sneak peek into her shop and hard work! Check out out her cool designs at 42 Pressed!