Kent Aldrich is everywhere: from falling in love with World War II posters, cutting his teeth on metal type, and standing quite still as the elusive (and brilliant, we might add) man behind Nomadic Press. He refuses to be defined by printing parameters, rather, he deftly commands them in his letterpress work. Read on to find out more on the musings of this passionate printer.

THE NOMADIC PRINTER I was born in 1964 and I am still living today. I was fascinated with type forms as a young child and designed a couple of fonts (leaning heavily toward an art deco style) when I was in second grade. I have lived most of my life in the Twin Cities of Minneapolis and St. Paul. I have been married for 22 years to the same woman, Emily, with whom I have 2 children. I ride a scooter with 46 rearview mirrors on it, I shoot a decent game of pool, and I like a beer with a strong hop flavor.

TEXT, FUN & ROCK ‘N ROLL When I was fourteen years old, I had fallen in love with poster art: Rock posters, French night club advertisements, WW2 recruiting posters. Anything intended to be tacked upon a telephone pole or hung up on a wall. So, I stole a composition stick (and the first line of a dead form) from a local jobbing shop and rode a hound down the Mississippi river to Winona. Once there, caught in the yellowing teeth of a full moon midnight, I sought out a lonely gravel crossroads where I met with the Devil and sold my soul for to print.

From there it was a series of graphic arts classes in high school,wooden renaissance festival presses, and a 3 year run-in with Coffee House Press and (the then just established) Minnesota Center for Book Arts. All of which conspired to push me into starting my own print shop, The Nomadic Press.

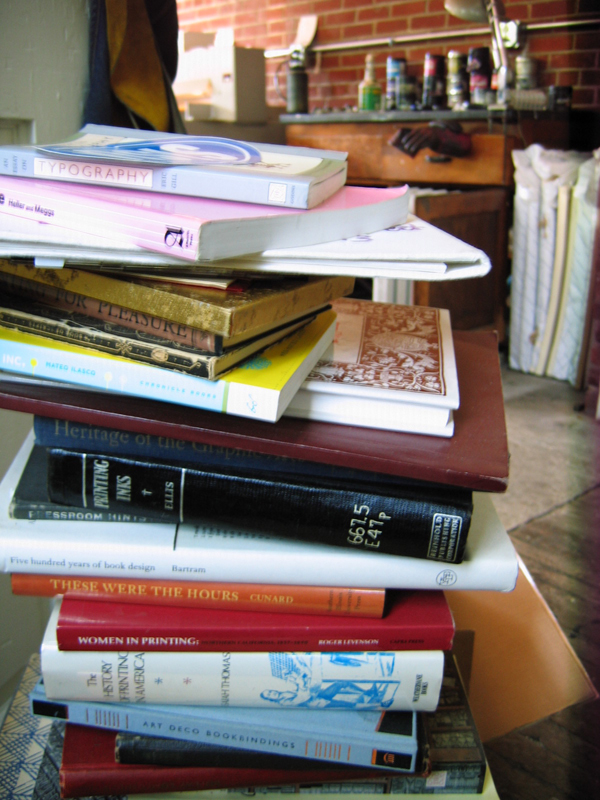

MAJESTIC MINNESOTA The building housing The Nomadic Press was built in 1914. The brick, from which it was built, was fired in a kiln a mile and a half away on a bluff overlooking the Mississippi River. It was originally a Mom & Pop grocery store and sat at the end of a street car line. The owners lived above the store, as did my wife and I for the first 7 years of our owning the place. With maple floors and woodwork and big, west facing windows, the interior of The Nomadic Press has been laid out following suggestions published in Mechanick Exercises on the Whole Art of Printing (1684) and has been outfitted in the style of a jobbing shop from the 1930s.

Nomadic’s press stable includes: two hand fed Chandler and Price old style platen presses (10 by 15 and 8 by 12), an automatic feed Kluge (12 by 18), a Vandercook Universal I (with a power carriage, adjustable bed and take-up tapes), the Pearl (more on that press later), and a spattering of table-top hobby presses.

PRINTING LEGACIES Al Schwerdt showed me how to print clean work using inking balls and a solid oak lever press and taught me the satisfying importance of the ethical and respectful treatment of both clients and vendors.

Allan Kornblum, who founded Coffee House Press, and spent years patiently teaching me the craft of letter-spacing and the fine art of keeping my hands out of the hungry jaws of a roaring platen press.

Will Powers, who made it plain that a printin’ man is a man well satisfied.

And Joseph Moxon, who said it best when he said; “As he set this stick of letter, so he sets on till his page is out”.

THE DAILY GRIND When I was first learning to print I slept on the floor of the print shop with my head on the feet of the press. Every morning I drink a hot cup of Van Son rubber base ink. Black. I have a ream of 80 pound text for lunch and bowl of 24 point em quads for dinner. My children were conceived in a room directly above my C&P 10 x 15. Too much information? Probably. But, heck yes, I print full time! For the last 26 years I’ve printed full time, and I plan on dying with my stick in my hand (that’s composition stick).

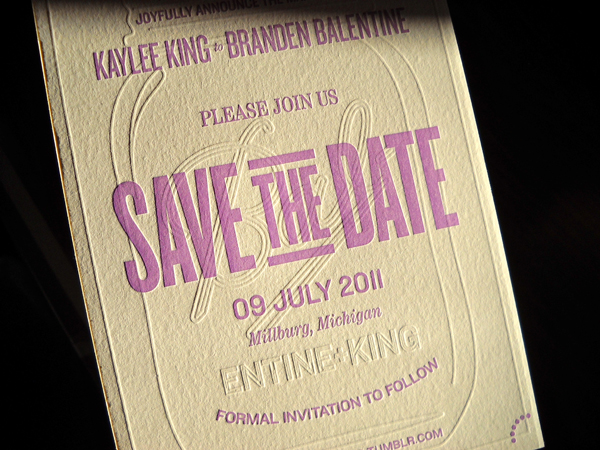

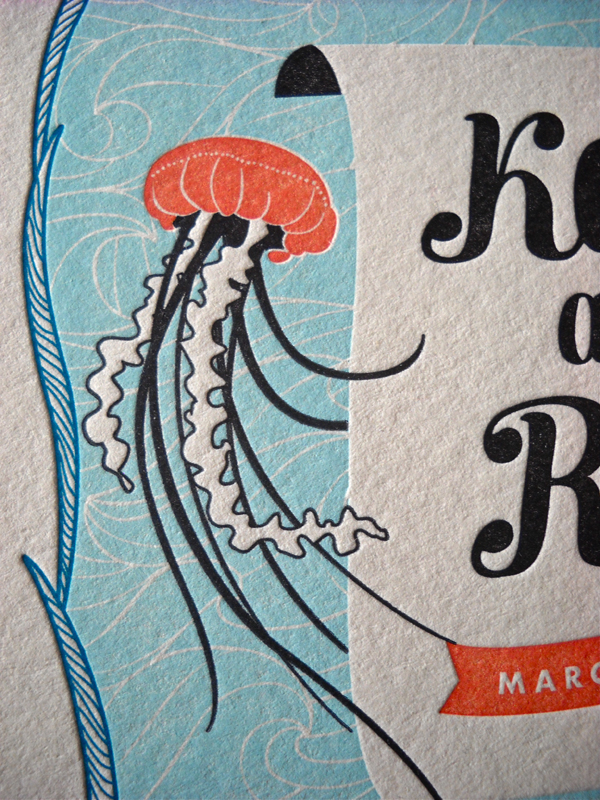

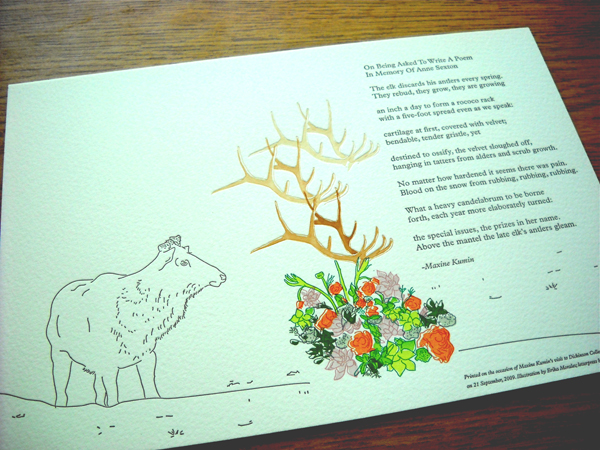

DESIGNED FOR PRINT Letterpress printing is, by its nature, a process who’s accessibility and immediacy demands a skillful confluence of art and craft. It is not enough to know how the press is best run, nor is it at all well enough to fix a pretty picture in one’s mind. Rather, a holistic knowledge of afore and after is called for.

ALL THAT’S FIT TO PRINT When I am designing my own work, and am using movable metal type, I like to set an element and print it. Then I set the next element and print that. And so on ’till the work is finished. It is a process that often finds me printed into a corner. And it is always a thrill to find the word, or type face, or ornament or color which, when laid down with the rest, finally pulls it all together and lets me walk out clean. When designing for clients, it all must be planned out beforehand though. Then I set great store in knowing what kinds of printed pieces they do /not/ like. Here be monsters.

PRINTER’S PARADISE The Nomadic Press is run out of a brick building which was built in 1914. Last year, Emily and I paid off the mortgage, and we now own the building outright. I have done printing for Nelson Mandela and Vaclav Havel, and I have produced work for the King of Norway and the Palace at Versailles.

BOXCAR’S ROLE Having begun my letterpress printing career more than a quarter of a century ago, and having cut my teeth on metal type, I have worked with all manner of plates and blocks: Linoleum and end grain maple, electro-plate and zinc, copper, lead and magnesium. All have graced chase and bed here at The Nomadic Press. And they have all served adequately well.

But the photopolymer printing plates that Boxcar has developed, and now sells, are a printer’s dream come true. They are quick and clean and precise and they provide a seamless interface between my state-of-the-art presses (circa 1890s) and the cutting edge graphic design technology of today. And they impart, into soft papers and onto hard, a crisp impression that does a printer proud. It is hard to imagine the occurrence of the 21st century letterpress revival without Boxcar steaming into the station and hauling most of the freight.

PRESS HISTORY You always remember your first press. As is so often the case, I simply mentioned that I was looking for a press to someone who had talked to a person who knew of a clamshell platen that somebody had somewhere. So, for fifty bucks, I bought a 7 x 11 inch Pearl press, a Paragon guillotine cutter and a cabinet of type. And I had to get them out of a basement by the end of the week. I still print with her (and oh, the sweetness of her kiss!).

SHOP TIPS Know in which direction the grain of your paper runs, and be very kind to your register pins.

WHAT’S NEXT Big picture; I am working to build another 21% growth in gross over the previous year. Small picture; I hope to be able to print something using Pantone Mixing System number 332 (uncoated).

Huge thanks to Kent for letting us get a sneak peek at the fabulous Nomadic Press!

Photographs provided by Kelsey Johnson and Andrew Hine