Chris Paul, of North Carolina-based Old North State Press, shares with us how an evening introductory printing class flourished into a love for printing machines and letterpress. From there, with the help of numerous, generous mentors and his wife/partner, Danielle, he has immersed himself happily in the craft. Read on to discover how Chris passes on the knowledge he’s learned with the letterpress community.

CRAFT AND TRADITION

At Old North State Press, we are dedicated to preserving the tradition and craft of fine letterpress printing. We started our journey with the acquisition of a simple cylinder press in 1998. The studio now boasts an impressive array of heavy, outdated machines and equally obsolete related equipment, all meticulously maintained and loved.

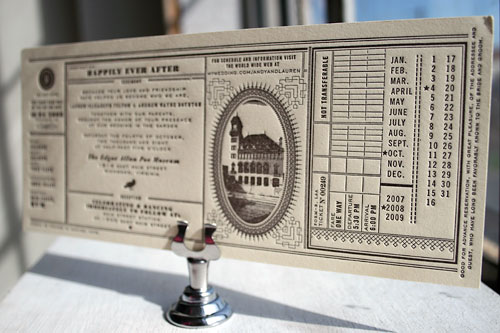

In addition to supporting custom client work where the unique characteristics of letterpress printing is desired, the press produces original designs for stationery, note cards, wedding invitations, birth announcements, broadsides, and other printed matter.

I am a classically-trained designer and typographer and completed my MFA in Design at Yale School of Art in 1995 where I was first introduced to traditional printing methods. I enjoy fretting over the details and coaxing beauty from these iron beasts. My wife and partner, Danielle, is a fearless editor and etiquette expert. She has a Masters in Communication. This background comes in quite handy with our clients and the work they bring us. Danielle has a keen eye for fine presswork and ensures every piece we produce measures up to our exacting standards.

GETTING THE PRINTING BUG

Back in the early 90s, while in grad school, a few of us signed up for introductory printing classes, taught once a week on Thursday evenings, at the university printing facilities. The start of the digital era in design was in high gear and while many of us had been working in print for some time, our understanding of the tradition and craft of printing was limited. I had only seen pictures of metal type in books. Greer Allen, the former University Printer at Yale and one of the instructors, would regularly shake his head at how little we knew! He was, however, a truly patient and enthusiastic teacher.

In the class, Greer and a local book designer, Howard Gralla, taught us how to set type by hand and print our simple creations on a Vandercook proof press. I was hooked immediately. The exquisite mechanics. The rich history. The endless possibilities. I vowed then and there I would learn as much as I could about letterpress and, one day, find a press of my own.

I got a job doing design at IBM in 1995. In 1998, Danielle and I moved into our first house. It had a garage and thus, room for a press. We acquired our first press, a Vandercook No. 3, soon after moving in.

THE SHOP: A CREATIVE HAVEN

Because I work in software design, I tend to think of everything as versions. We’re currently on version 3.0 of our shop which we built in 2014 after moving to the Charlotte, NC area. Our shop is about 400 sq ft and houses all of our equipment. We still have the original Vandercook No. 3 but have since added two late model 10×15 Heidelbergs. The first Heidelberg was re-built from the ground up by Graeme Smith while he was with Whittenburg in TN. It is a beauty and our most prized piece of equipment. The second Heidelberg was acquired this past summer and is in need of a good cleaning and some serious TLC. Our intent is to dedicate this second machine to foil and die-cutting.

Because of my desire to learn everything I could about traditional letterpress, I also got into hot metal typecasting in the early 2000s. With the help of some amazing mentors, I was able to acquire an English and American Thompson Sorts Casters and a small library of matrices. I first learned to cast type under the thoughtful tutelage of Pat Taylor, former proprietor of Out of Sorts Type Foundry, and Rick Newell formerly of Heritage Printers in Charlotte. We also have many cases of metal and wood type, an antique John Jacques & Son paper cutter,and all the various accoutrements you’d expect in a working shop.

What we love most about our shop is having a dedicated, climate controlled space to design, make and learn. Letterpress has a deep heritage, and these machines teach us something new every time we use them.

NORTH CAROLINA COOL

Our shop is located on our property in an older, heavily wooded and secluded neighborhood south of Charlotte, NC surrounded by horse farms. We are 10 minutes from historic downtown Waxhaw and 30 minutes from Uptown Charlotte.

PRINTING MENTORS

I am deeply indebted to many for the generosity of their time, patience and wisdom. I first learned to print from Howard Gralla and Greer Allen while a grad student at the Yale School of Art. Rick Newell helped me acquire my first press and type, and he taught me what it means to run a shop. Pat Taylor, Rich Hopkins, Mike Anderson, and Jim Walczak inspired me to give typecasting a go and encouraged me to keep at it.

Fritz Klinke of NA Graphics took me under his wing early on and instilled within me a love of the process, hot metal type, and the journey of “figuring it out.” Elias Roustom of EM Letterpress taught me more than a few tricks of the trade along the way and his work continues to inspire me. Further, where would any modern day letterpress printer be with a reliable rigger? Pete McFee has moved every press I’ve ever owned and introduced me to electricians and repair techs who know and appreciate these old machines. Priceless!

I’m also indebted to and inspired by the many designers, printers, and clients I’ve met along the way who have shared hints, tips and techniques and pushed me to learn and make.

Last but not least, sincere thanks to my partner, Danielle, who has taken this journey with me, providing support and encouragement at every step.

PART TIME PRINTER, FULL TIME FUN

I am not yet a full-time printer, however, I spend as much time as I can in the shop and am fortunate to have clients who keep coming back and pushing me to learn new things. I suspect one day I’ll be doing more printing than not, but we’re still a few years off from that goal.

THE CREATIVE PROCESS

By day, I work in technology, designing digital experiences and products. Thus, my design process for letterpress can seem to be a bit fragmented. Sometimes, an idea occurs to me and I have to get it out as quickly as possible. Other times, a fragment of an idea may sit in my head, stewing, for a few weeks/months before I act on it. Occasionally, I will start with a technique I want to learn…like die-cutting or foil stamping and create from there.

While I end up sketching quite a bit in the late process, my early iterations are almost always via writing. My sketchbooks have more words than drawings. I have an old t-shirt from Emigre with the slogan “Design Is A Good Idea” and this embodies how I approach what I do. Once I think I have something, I’ll sketch around the idea and poke at it multiple times before attempting to start something digitally.

There is so much great work out there, you never have to go too far for inspiration…old and new.

PRINTING FEATS

I’ve been a member of the American Typecasting Fellowship for over 15 years and am a graduate of Monotype University, both run by the amazing Rich Hopkins. Our shop was one of 15 that Rich choose to feature in the book, The Private Typecasters, hand-printed and bound by Henry Morris at Bird & Bull Press. We’re also featured in the book, Vandercook 100.

Most of all, we are proud of our ability to continue to learn, make beautiful things and share what we know with others.

PRESS HISTORY

Our first press was Vandercook No. 3 Proof Press, acquired from the Charlotte Composition Company with help from friend and mentor, Rick Newell. I won’t tell you how little I paid for it, but I will say they almost paid me to haul it away. I love that press because it is so simple.

One of our first real print jobs on the Vandy was the birth announcement for our son, Aidan. We did the same when Erin came along in 2003. In 2017, we printed Aidan’s high school graduation announcement on our Heidelberg.

BOXCAR’S ROLE

Boxcar has been an inspiration from the beginning: I distinctly remember my first encounter with Boxcar and how elated I felt that someone was actually running a successful business doing letterpress! I then invested in the Boxcar Base and haven’t looked back. I use Boxcar Bases on each press I own and Boxcar processes all my photopolymer plates.

What I love most about Boxcar are two things: One, Harold Kyle and the team have continued to innovate from the very beginning…helping to modernize letterpress and make it relevant for today. The Boxcar Base and Swing-Away Lay Gauge are two prime examples. Second, the team at Boxcar shares everything they know and have helped me be a better printer. I’ve not found anyone more dedicated to the current community of designers and printers.

SHOP TIPS

Perhaps a useful letterpress printing technique? If you’re just starting out with a press like a Heidelberg, focus first on mastering the paper feed. There are so many nuances to feeding and once you master it, your life with be less frustrating and your printing faster and more satisfying.

An old technique I found out about recently, the Flying Dutchman, can help you get tighter registration on a Heidelberg by taming paper bounce:

Read everything you can get your hands on about technique and setup and don’t be afraid to fail. Successfully printing on these old machines can be challenging. The most important piece is to keep at it. It takes time and experience to encounter the various challenges that will present themselves. When they do, step back and think. Frustration, failure and disappointment are how we learn.

I founded the Facebook Letterpress Group in 2007, and we are currently 4500+ members strong. Included in the group are both active and many retired printers with great experience and know-how. I turn to the group regularly when I encounter something I haven’t yet figured out. The team at Boxcar, the Letterpress Commons, and Briar Press sites are also a tremendous resource. Don’t be afraid to ask questions and keep asking until you understand.

WHAT’S COMING NEXT

This might actually be the year we get more of our custom stationery line up and running. This is a goal we’ve had for some time…but…life is what happens when you’re busy making other plans! Now that our children are older, we have more time to dedicate to our various printing projects.

We also held our first letterpress workshop recently, partnering with the Charlotte Chapter of AIGA. It was a big success so we expect to do more of the same and help spread the love for letterpress and type in the Charlotte region.