The printing life of Salem, Ohio’s very own Keith and Jamie Berger of the Cranky Pressman has catapulted since they first set-up shop more than three decades ago. From tight-registration and spot-on prints to changing into a decidedly full-on letterpress shop, the duo creates expertly crafted letterpress prints. We caught up between in runs with the brothers to talk shop, see how the printing world has changed, and keeping up the tradition of old-fashioned know-how.

ALL IN THE PRINTING FAMILY KEITH BERGER It was the 70s and my father was a Graphic Artist and worked with printers. He told me, a lazy teenager without any interest in school, to “learn a trade” and printing seemed the answer. After a 2 year vocational school stint I was ready to go out and be a printer. I worked in the prepress departments, doing camera work, stripping and color separations. It was 1983 when I found a local small print shop where the owner was selling his business. I have had the shop ever since. Fighting the good fight.

=

=  (A fresh stack of letterpress Cranky Bucks notes. Don’t tell the cops!)

(A fresh stack of letterpress Cranky Bucks notes. Don’t tell the cops!)

JAMIE BERGER: Cranky Pressman is a partnership between brothers, Keith and myself. The Cranky brand was launched in 2003 but the partners are good old boys who have been around much longer than their Victorian era mascot.

In 1983, Keith bought a printing business that had been around since 1938. The shop likely started as a letterpress printery, serving the local business community in Salem, Ohio, which was a thriving industrial town at that time.

Much of the equipment was very old when Keith first acquired the place, from the Chandler & Price platen press (retrofitted with an electric drive motor) to the various pieces of old bindery apparatus such as perforators, drills and cutters. Of course the old shop also had many antique line-cuts, wood and metal type, plus the 1,000s of bits and pieces of furniture and other standard letterpress printing supplies.

(Pica the cat: the mascot of Cranky Press near a beautiful specimen of vintage wood type)

(Pica the cat: the mascot of Cranky Press near a beautiful specimen of vintage wood type)

I was living and working as a graphic designer and art director in New York City in the mid-1980s. At that time in my career, pretty much all of the work I was involved with was print-based. Most graphic design materials at that time were printed with offset lithography including slick 6-color presses. However, letterpress was often preferred for projects like corporate event invitations or when a classy personalized presentation was required.

(Business card for Parse & Parcel that includes foil stamping and letterpress printing on a custom duplexed stock, design by The Studio of Christine Wisnieski)

(Business card for Parse & Parcel that includes foil stamping and letterpress printing on a custom duplexed stock, design by The Studio of Christine Wisnieski)

The 80s print shop did have small offset lithography presses which were the workhorses on day to day jobs. Beside invitation work though, letterpress at this time was mostly used for imprinting packaging and other pre-converted materials, die-cutting, scoring, numbering and foil-stamping.

We were always fascinated by the array of old machines, type and cuts around the place when I was in town visiting. Actually, they hand-set and printed my wedding invitation by letterpress in 1988.

Over the next decade or so, with the advent of the Macintosh and continued growth of lithography and eventually digital printing, the traditional craftsmanship of printing began to fade around the shop. In the early 2000s, Keith felt it was time to change and get back to craft-printing.

(Close-up detail of a piece we did Carly Rounds at Design 360)

(Close-up detail of a piece we did Carly Rounds at Design 360)

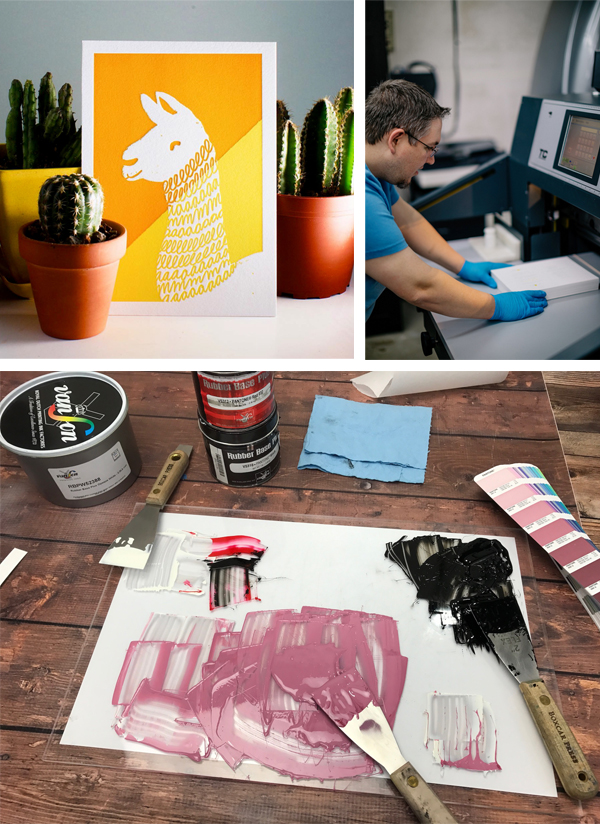

Cranky Pressman, an all-letterpress shop, was born in 2003 [and] now serves the graphic designers, ad agencies and other creative businesses throughout the country.

THERE AND BACK AGAIN, A PRINTSHOP’S TALE KEITH: The shop I mentioned [earlier] came with a C&P, a Miehle Vertical, lead type, lock-up table and a cream puff of a Heidelberg Windmill that the original owner hardly used and was unable to train me on. Me being the ever savvy businessman decided that offset printing was the way to go. So I traded in that cream puff of a windmill on a fancy single color offset.

Meanwhile I was numbering, perforating and die cutting on the hand feed and Miehle. Eventually, I started doing stuff like napkins and book covers which were fun but made no money. The offset seemed to be going the same way. Sales were becoming tough-going and everything was changing to digital. This is when we, Jamie and myself, saw that letterpress as the way to go. To make a way too long story short, eventually we converted to all-letterpress and I sold that offset and brought back in a another Windmill exactly like the one I had sold years earlier!

JAMIE: Other than the wedding invitation mentioned above, my involvement with letterpress was mostly as an observer and occasional print buyer until I moved back to Ohio in 2012. I mainly look after the creative and marketing for Cranky Pressman. This has meant spending a lot of time studying and learning about the craft, more as a journalist than a hands-on printer.

However, when you spend so much time around printers, working closely on projects as a designer and/or art director, you get the urge to have a go and making some prints yourself.

Since relocating and working out of the letterpress shop, I’ve begun to dabble in some small hand-set pieces, mainly for Cranky Pressman promotions. This inspired me to begin working in print doing personal printmaking, including hand-setting, linocuts and woodcutting.

OPULENCE IN OHIO KEITH: Our small business was located downtown in the depressed small town of Salem, Ohio, on the second floor in a back alley. What could go wrong with that! But the invention of the internet helped save the day. Then again being that savvy visionary businessman, I figured that 10,000s of lbs of equipment should probably not be located on the second floor of a 125 year old building. Luckily there was a freight elevator, so we packed up the old print shop that was in the same place since the 50’s and moved it a block and a half away. Moving a letterpress shop is a story in itself. Fortunately, I have blocked the experience from my memory so that I can begin to function fairly normal again.

(Letterpress printed and die-cut gift card holder for Lucille’s BBQ)

(Letterpress printed and die-cut gift card holder for Lucille’s BBQ)

JAMIE: After being at the same location since the 1950s (the first owner started the shop at another location in the 30s), the shop was recently moved two blocks down the road but in the same small town of Salem, Ohio.

The former location was on the 2nd floor of a 19th Century industrial building that was being converted to shopping and dining businesses. This was the ideal time to move the letterpress shop into a more appropriate ground floor workshop space.

Salem, is a historical old town in northeast Ohio, exactly halfway between Cleveland, Ohio and Pittsburgh, PA. There are still some factories in town but many of the old industrial buildings are empty. The town came upon some bad times, with factories and businesses closing, starting in the 1970s through the end of the last century. The closest bigger town in Youngstown, which suffered the same sort of economic downturn as Salem, but on a larger scale. The surrounding areas are mostly farmland.

Being more of an outsider myself (my family moved to this area from nearby Akron when I moved away to college) I can honestly say, the local folks are a hearty bunch. They can sometimes come across a little gruff (they’ve been through a lot after all) but there are many who never left and never intend to.

I am happy to report that over the past 10 years or so, it seems as though the little town is breathing new life. There are new shops, bars and restaurants around. The local high school stadium was recently renovated and other civic improvements are underway. Strong local historic and preservation groups are key to a lot of these good things happening around town. The Historical Society itself also went through a fairly recent expansion and the displays there are very well done and interesting. It nicely showcases the town’s rise, fall and rising again.

The space we recently moved from had some good old-world charm, with wooden floors and a rickety freight elevator. Our new workshop is much better organized, brighter and built for letterpress production on one side, and letterpress creative printmaking on the other side. We don’t yet have the place fully decorated or broken-in but everyone is happier working in the new space.

GOOD NEIGHBORHOOD EATS My favorite two local places to go out are among the oldest and most, shall I say, down to earth.

For eating (and drinking) you can’t beat the honest food and atmosphere at Mike’s Penn Bar and Grille. For pure drinking, soaking up local color and pool playing, I like Fernangeles. They don’t have a website and their Facebook page is only half-built, but is was the 1st or 2nd licensed bar in Ohio. The wooden walls in the bar area have paintings from the 19th Century that were done by travelers in exchange for room and board. Please note, you will likely get a good sampling of a variety of local yokels if you visit, so don’t wear your best clothes.

(A shot of the printmaking-studio-side of the shop. You will see Jason in the shot again. He is such a ham!)

(A shot of the printmaking-studio-side of the shop. You will see Jason in the shot again. He is such a ham!)

PRINTING MENTORS KEITH: Early on I used a hot type setter that had Intertype and Ludlow typesetting machines. Bob Lesh is his name and he loved the trade of hot typesetting and we would discuss the history, and more interestingly, the system of a letterpress shop. We both believed that the usefulness of hot typesetting and letterpress would always have its place. Easier said than done, especially for the hot type, I am trying to save his vast collection and keep it viable for future generations.

JAMIE: Current Favorites: Dafi Kuhne, Church of Type, Brad Vetter, Starshaped Press

Been Around: Hatch Showprint, Lynd Ward, Albrecht Durer, Guadalupe Posada

DESIGNER + PRINTER KEITH: Mainly a printer but designer’s were originally printers so both I guess.

JAMIE: I studied and began my career as a graphic designer. I then spent most of my career working as an advertising art director. I am now (re)learning to be a graphic designer and printmaker at a ripe old age.

FULL-TIME SHOP FUN JAMIE: Yes, the shop is a full-service commercial letterpress shop.

PRINTING FEATS KEITH: Staying in the printing business for 30 + years. Although it has never been pretty it has always been interesting.

JAMIE: I had two prints (1 linocut and 1 woodcut) accepted in this past year’s Regional Artists juried show at The Butler Institute of American Art. So I guess I am beginning to learn how to print a bit.

PRESS HISTORY KEITH: It was not a letterpress, but an AB Dick duplicator that I ran in my living room!

JAMIE: Never owned a press myself but enjoy using others!

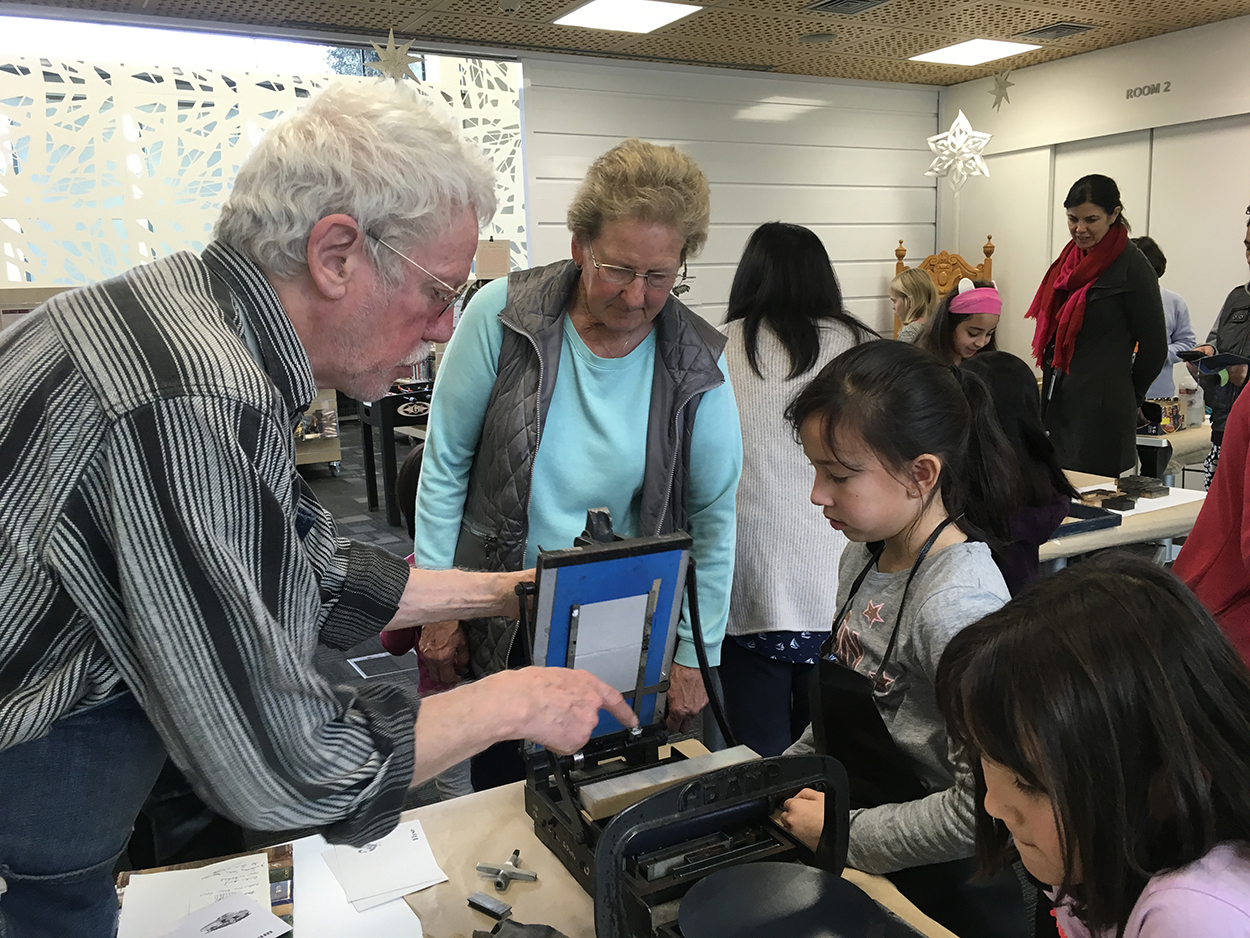

( Jason Vaughn (our head pressman) discusses printing specifications with Keith (at left).)

( Jason Vaughn (our head pressman) discusses printing specifications with Keith (at left).)

BOXCAR’S ROLE JAMIE: The Boxcar Press website and blog has been an inspiration and valuable resource for letterpress information over the years.

SHOP (AND LIFE) TIPS KEITH: Listen to your elders. They may have a different perspective but you can always modernize their advice.

JAMIE: I am still learning so you may not want any of my tricks if I had any!

WHAT’S COMING NEXT KEITH: To save the hot type and letterpress system and to “learn a trade.”

JAMIE: We will be continuing to set up, organize and decorate the shop. We hope to have more events such as workshops and visiting artists working in the space. We also are working on some new bindery and printing offerings to be announced.

A double round of applause & thanks out to Keith and Jamie of the Cranky Pressman for letting us take a sneak peak at their wonderful printing realm!

=

=  (

( (Pica the cat: the mascot of Cranky Press near a beautiful specimen of vintage wood type)

(Pica the cat: the mascot of Cranky Press near a beautiful specimen of vintage wood type) (

( (

(

(

( (

( (

(