With the combined talents of illustrator Shino and hands-on printer Ken, Fugu Fugu Press of Pasadena, California has been buzzing since its debut about four years ago. The printing pair muse over moving stories, churning out vibrantly colored letterpress pieces, and talking shop with us about the things they can’t live without, from great design to irresistible jazz.

LAUNCHING LETTERPRESS Shino went to Art Center in Pasadena for a degree in illustration, and worked as a freelance illustrator for about 13 years before starting Fugu Fugu Press. While freelancing she mostly did editorial illustration for print publications and some website work. Freelancing was a rewarding, if sometimes wild and unpredictable experience. She had the pleasure of working on pieces for Time magazine, The Wall Street Journal, The Boston Globe, and Penthouse magazine. She did storyboards for movies and illustrations for a number of children’s books, and a regular column for the LA Weekly. It was interesting and fun to get different assignments and work with various art directors, but she’s very glad to be her own “art director” now with Fugu Fugu Press! Ken is a California State University, Chico grad and has a history of joining bands and roaming around the country playing music. He’s also done a fair amount of playing piano for musical theater productions, church services, teaching music to kids, recitals, and has worked on a number of TV shows and movies as a music editor along the way. He also likes puttering around with old machines. When he and Shino set off to launch Fugu Fugu Press he was very happy that his official job would include motor oil, knob twisting, and getting dirty.

IN THE BEGINNING While freelancing, Shino worked for a couple of friends who owned another letterpress greeting card company. She learned how to print on their C&P and Kluge there. They also encouraged her to design for them, which she did.

PERFECT COLOR IN PASADENA Our print shop is officially in it’s 3rd location so far. When we started looking for presses, we followed up on a Craigslist ad for a printshop in downtown LA that was going out of business and selling its presses and other hardware. We bought a Heidelberg windmill, C&P, a big stone imposing table and Challenge paper cutter from the owner Davy Chao at Olive Leaf Press as soon as we saw them… and then immediately started panicking about where to move them all to!

Luckily, Davy wasn’t in all that big of a hurry to actually close his shop, and we were able to keep the presses right where they were for about 6 months while we looked for another location. This was a very fortunate arrangement as Davy was very helpful with getting Ken up to speed on how to print well on the Heidelberg and C&P. Ken and Davy would often be printing next to each other on separate projects, but it was nice that Davy was always glad to lend a hand…although he wasn’t too sure about the part where you intentionally make an impression while printing!

We did eventually find a place closer to us in Pasadena and made the move. We liked it a lot there in the new location, and stayed there for about 5 years. We did holiday pop-up shops there, and hosted “open studio” weekends where our friends would come and sell what they made. Unfortunately the roof leaked whenever it rained though (sometimes right on the presses or paper), and after a while we started looking to move again. When we bought our house, we did a little garage conversion and moved everything into the garage. People talk about how bad traffic can be in Los Angeles.. but our commute from the kitchen to our printshop is about 30 seconds! It’s great! We’ve talked about maybe opening a workspace kind of shop at a “retail friendly” location at some point, but until then.. things are nice and we’re happy with everything as it is.

PRINTING MENTORS Hiroshi and Karen, the former owners of the company that Shino worked for, taught her how to print. Ken learned with Davy in Davy’s shop before we moved everything to the Pasadena location. Ken was very glad to have Davy there to help him learn the hidden secrets of running a windmill and getting the printing to look good. As far as inspiration, we looked to the beautiful work of Egg Press and Hello Lucky! among others. Great designs and great printing. They were definitely strong influences early on.

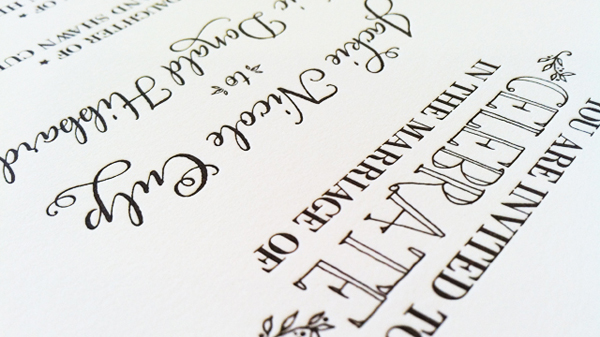

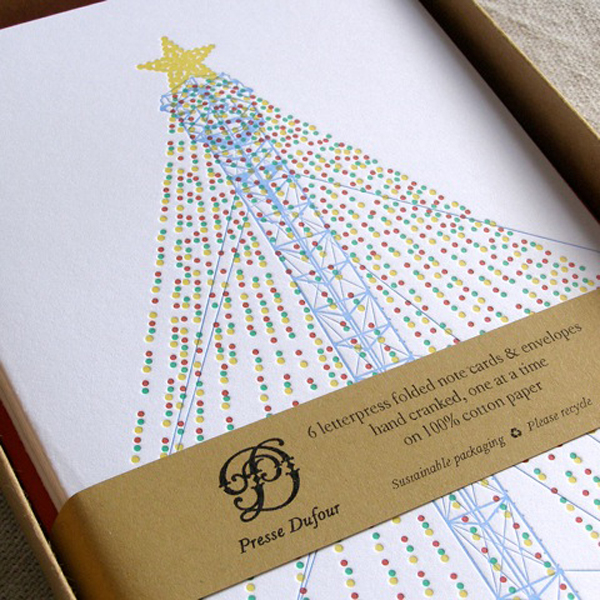

CREATE AND PRINT Shino is the main designer. She doodles constantly, and looks at images everywhere for inspiration. She is an illustrator by training, so her designs tend to be more image-oriented, not calligraphy or type heavy. We toss ideas back and forth all the time to help get ideas going, and Ken has done designs for some custom work we’ve done for people.

FULL TIME FUN Fugu Fugu Press is Shino’s full-time job now. It has been for about 4 years now. Ken prints and also has a regular thing playing the piano in the bar in the evenings at the Hotel Bel Air, and plays gigs on the weekends in different spots around Los Angeles with his jazz band friends.

PRINTING FEATS The first time we did the stationery show, and started writing orders. It was back in 2008. Getting ready for that show was a major hurdle. Just getting everything printed in time, and getting everything to New York in time, and getting ourselves there in the time took a lot of preparation and, well.. money. And there was no guarantee that we would get enough new accounts to make it worthwhile. We were very happy to come back home feeling good about having done that show.

PRESS HISTORY A 12×18 C&P and 10×15 Heidelberg.

BOXCAR’S ROLE When we got our presses and got into this business we really felt like there was little to no support group or information to help us along. We heard about Boxcar Press and visited the site regularly. We were so relieved to see that they had answers, and were making bases and plates, and had easy to find .pdf’s of important and hard to find things like the Heidelberg windmill manual and parts list. (We’ve used the parts list to order parts from press dismantlers and vendors.) And we’re glad to see that Boxcar is innovating and helping push the craft forward. We were just talking to a fellow letterpress friend of ours at the most recent stationery show about Boxcar’s new mechanical “flag” guide for the lay gauge bar that aids in getting the sheet to be printed to slide reliably into the correct position for registration without skipping the pin. We have our own method for doing that.. but are secretly really wanting to give that thing a try…

SHOP TIPS Use violin rosin to get some stickiness on your roller tracks and maybe shim your trucks to get “ghosting” under control. Oil your presses. Whatever you do, don’t die cut directly on the platen. Don’t let any pins you might be using on your guides hit your block, form or wooden type. Don’t “force” your press to do anything in doesn’t want to do.

Those little “doorstop” shaped sheet lifters you can get to lift the back of the pile on the feed table can absolutely do wonders along with the air blast in getting “double sheeting” problem under control on a windmill. And speaking of double sheeting, there’s that weird little trick where you reach behind the press and lift that little spring loaded piece that rides in the groove back there, and get your flywheel to temporarily spin… backwards. Great for clearing a jam where your press has double or triple sheeted and has gotten locked up, and you can’t manually advance your way through the jam. Our press tech friend Bob showed us that one the last time he was over to our place, and as far tricks and tips go and… yep…that was a good one to learn. These are some of the things that we’ve found that worked for us, but as with anything, proceed with caution and at your own risk whenever trying anything new!! Let common sense be your guide!!

WHAT’S NEXT We will be doing more split-fountain stuff and die-cutting!

Huge heaping round of kudos out to Ken and Shino for letting us get the skinny on Fugu Fugu Press!