From expanding the bustling press shop floors to running the community-driven Flying Object gallery/bookstore/community letterpress space, Guy Pettit has been passionate about spreading the word (and a bit of ink here and there) about the wonders of printing. The Massachusetts native hopped on the line with us at Boxcar Press to talk about the richer things in life: inking up the rollers, working with the fabulous community at Flying Object, and of course, his dual love of letterpress & doberge cake.

UP CLOSE WITH GUY PETTIT I love doberge cake from Gambino’s Bakery in New Orleans, Louisiana. That’s where a lot of my family is from. Doberge has about a thousand layers of dessert pudding alternating with white cake. I’m about to eat a piece. It’s really all that matters.

UP CLOSE WITH GUY PETTIT I love doberge cake from Gambino’s Bakery in New Orleans, Louisiana. That’s where a lot of my family is from. Doberge has about a thousand layers of dessert pudding alternating with white cake. I’m about to eat a piece. It’s really all that matters.

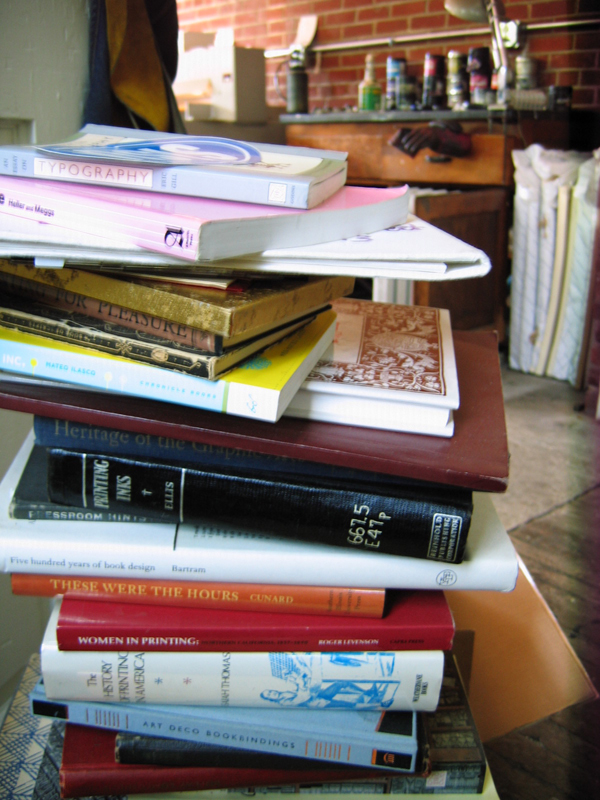

INK IN THE BLOOD I got started after borrowing a friend of mine’s Kelsey 5×8 while she was abroad for a year. I’m pretty closely connected to small press publishing and poetry, which exposed me to letterpress frequently before I actually knew what it was.

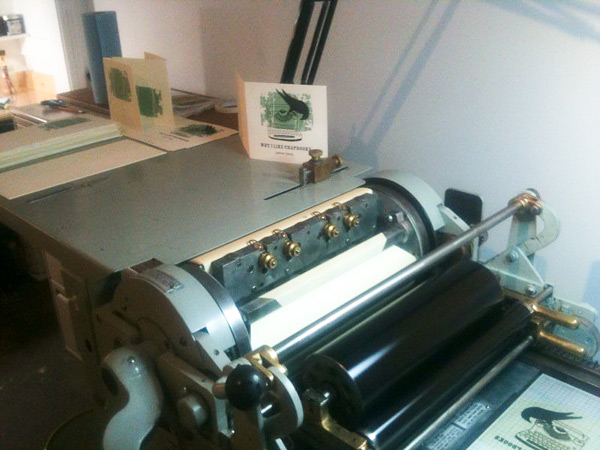

BRILLIANCE IN THE BAY STATE We’re located in an old volunteer firehouse on a historic common (aka a 17th century palisade – the biggest one of its kind) in Hadley, next to the Connecticut river. I’ve had to do a lot of renovations but the space keeps opening itself up in really exciting ways, almost as though it was the natural next step in this buildings career. There’s a belfry. The concrete floors were perfect for the heavy machinery. Oh, and we have a shower in the studio! And great stone terrace out front. It’s a beautiful space.

BRILLIANCE IN THE BAY STATE We’re located in an old volunteer firehouse on a historic common (aka a 17th century palisade – the biggest one of its kind) in Hadley, next to the Connecticut river. I’ve had to do a lot of renovations but the space keeps opening itself up in really exciting ways, almost as though it was the natural next step in this buildings career. There’s a belfry. The concrete floors were perfect for the heavy machinery. Oh, and we have a shower in the studio! And great stone terrace out front. It’s a beautiful space.

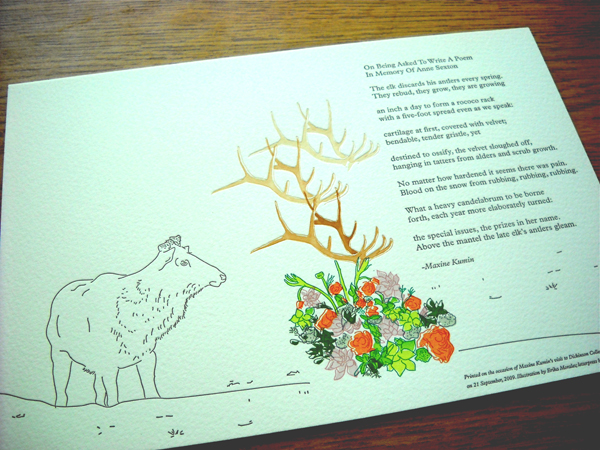

PRINTING LEGACIES My mentors are my friends, the volunteers who work at Flying Object, the 501(c)(3) non-profit gallery/bookstore community letterpress I run, all the wonderful people I’ve met working on chapbook presses, Emily B. Goodale of Brave Men Press, and Art Larsen.

THE DAILY GRIND I don’t print full time, but I do spend a lot time managing the non-profit, programming the classes, events, and exhibitions here, and doing design work. I’d like to have more time to spend on my printing projects but I’m not sure if it’s a goal to be a full-time printer. I like the variety that my current jobs affords me.

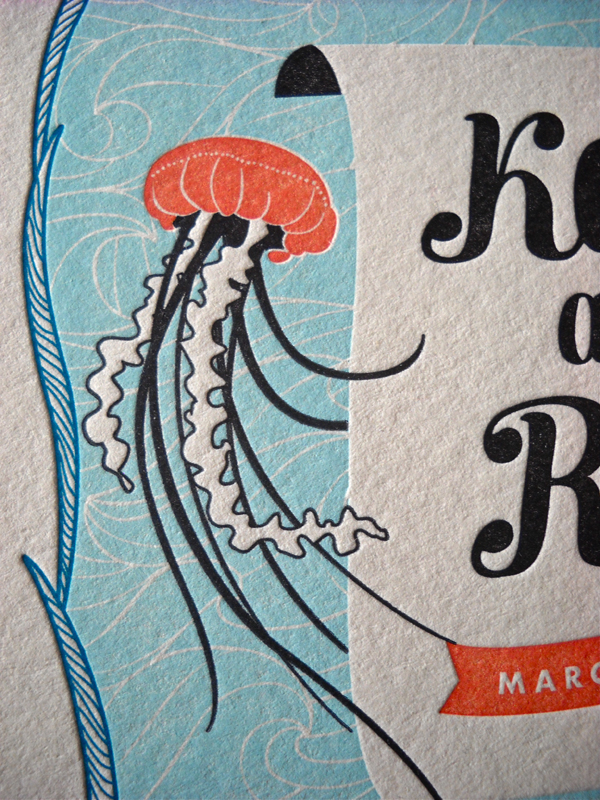

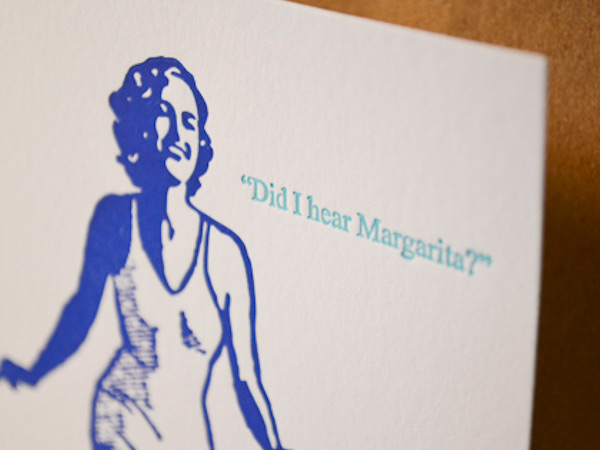

PRINTER’S PARADISE I’m a designer & printer, and a major influence of mine is the designer Alvin Lustig, many of the artists associated with Fluxus, finding ways to combine new technologies with letterpress, designing intuitively. I’m not trained – I studied creative writing and publishing in college – so my process is always changing. I’m always trying to push myself and break my own rules. But you could probably say my designs tend to blend photographic images with geometric shape. I’m also colorblind, so I’m constantly working with unconventional color combinations. Often people will look at a design of mine and look shocked by the color choices. I sort of enjoy that. I like mistakes. I’m always trying to incorporate them into my designs.

PRINTING FEATS I’m proud that Flying Object is really open to anyone who’d like to get involved and that letterpress is a major reason why people gravitate toward the space.

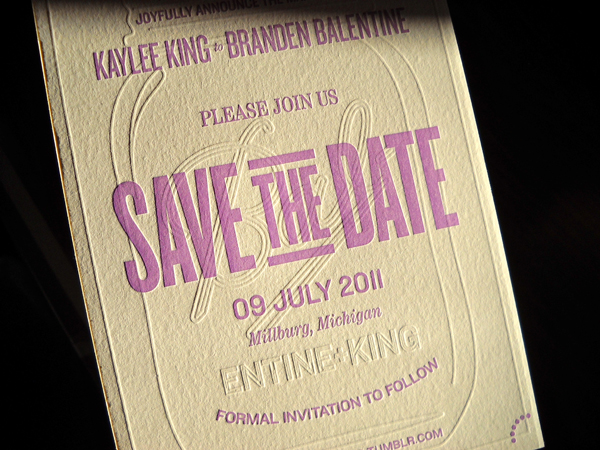

BOXCAR’S ROLE [Boxcar] has helped make printing with photopolymer plates, which we do a lot of, completely stress-free. I love the professionalism and forward-thinking attitude.

PRESS HISTORY After my year with the borrowed Kelsey, which I’d probably consider my very first press, I bought a Vandercook 4T. It was a big jump but I knew that it was a press I could share with a lot of people and was really the cornerstone behind opening Flying Object.

PRESS HISTORY After my year with the borrowed Kelsey, which I’d probably consider my very first press, I bought a Vandercook 4T. It was a big jump but I knew that it was a press I could share with a lot of people and was really the cornerstone behind opening Flying Object.

SHOP TIPS Find out what kind of printing (invitations, cards, books, pamphlets, posters, etc) you like best to do most and do everything you can to make that your focus. I’m a book lover and that’s who I seek out.

WHAT’S NEXT We’re expanding the press-room and converting the unit upstairs in our building into an apartment for a resident creative director, maybe for someone with letterpress experience. It’s going to be a big year!

Many thanks to Guy for letting us take a sneak peak at the wonderful world of the Flying Object shop!

Equipment, or toys, to date: 1917 vintage 10 x 15 C&P New Series hand feed; 1930’s vintage 10 x 15 Kluge Automatic; 1954 vintage 10 x 15 Heidelberg Windmill; late 40’s / early 50’s vintage Miehle Vertical V50; 1917 vintage Intertype linecasting machine; 1960’s vintage Ludlow Typograph; 1920 vintage 34 inch Challenge Diamond power paper cutter; 1940’s vintage Challenge floor model paper drill with round corner attachment; 1954 vintage Rosback auto stitcher; and a 1936 vintage 14 x 20 Baumfolder.

Equipment, or toys, to date: 1917 vintage 10 x 15 C&P New Series hand feed; 1930’s vintage 10 x 15 Kluge Automatic; 1954 vintage 10 x 15 Heidelberg Windmill; late 40’s / early 50’s vintage Miehle Vertical V50; 1917 vintage Intertype linecasting machine; 1960’s vintage Ludlow Typograph; 1920 vintage 34 inch Challenge Diamond power paper cutter; 1940’s vintage Challenge floor model paper drill with round corner attachment; 1954 vintage Rosback auto stitcher; and a 1936 vintage 14 x 20 Baumfolder.

There were a couple of times I was printing one way or the other seven 24 hour days non stop. Take note: The word “work” has not been mentioned. I was having too much fun to classify what I was doing under the category of “work”. Adding to it all, if I was moving printing equipment, well, that was fun in overdrive.

There were a couple of times I was printing one way or the other seven 24 hour days non stop. Take note: The word “work” has not been mentioned. I was having too much fun to classify what I was doing under the category of “work”. Adding to it all, if I was moving printing equipment, well, that was fun in overdrive. PRINTER’S PRIDE The many letterpress and offset printing production awards ranging from honorable mention to best in category presented by peers in the graphic arts industry. Also, a period of 44 years of moving printing equipment without any kind of mishap.

PRINTER’S PRIDE The many letterpress and offset printing production awards ranging from honorable mention to best in category presented by peers in the graphic arts industry. Also, a period of 44 years of moving printing equipment without any kind of mishap.

PRINTING LEGACIES I knew when I saw the miniature empire that Jen from Starshaped Press had built that it would be possible for me to do what I envisioned. I wanted the flexibility of creating my own schedule, the satisfaction of having people choose to spend their hard earned money on beautiful things that I design and print for them, plus the ability to take time off for kids when I need to (which will be March, 2012!). Paul Aken too, of course, without whom I would never have acquired any of my equipment and who I credit with helping me move closer to accepting imperfection. Still working on that.

PRINTING LEGACIES I knew when I saw the miniature empire that Jen from Starshaped Press had built that it would be possible for me to do what I envisioned. I wanted the flexibility of creating my own schedule, the satisfaction of having people choose to spend their hard earned money on beautiful things that I design and print for them, plus the ability to take time off for kids when I need to (which will be March, 2012!). Paul Aken too, of course, without whom I would never have acquired any of my equipment and who I credit with helping me move closer to accepting imperfection. Still working on that.