Since our last visit with ever-charming Ben Sargent of Sargent Brothers Printers & Typographers, we toured his wonderful Texas-based printing abode. A few printing treasures and tools may have been moved around & added to, but Ben’s cheerful demeanor while printing on his C&P 10×15 Old Series has never missed a beat yet. We caught up again with Ben between ink runs to see how the printing tradition still runs strong in his family (like father, like son), why the down-home feel of a good letterpress print shop can’t be beat, and scored some nifty inking tricks to use on an older platen press.

INK IN THE BLOOD I was born and grew up on the windy plains of the Texas Panhandle, where I learned the printing trade from my father. After getting a journalism degree from the University of Texas and putting in a few years as a reporter, I spent the next 35 years drawing political cartoons for the Austin American-Statesman. Retirement from that job gave me ample time to pursue my original trade, and I am enjoying it hugely.

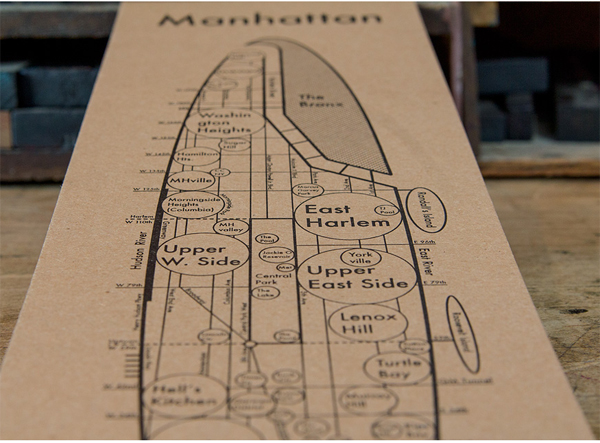

TEXAN TREASURE I’m fortunate enough to have a big enough property in South Austin to have built a nice little house (my one architectural accomplishment) as a home for the printing shop, and it is very satisfying to have a space built just for printing, not in the way of anything else. (Okay, it does also include a model-railroad layout along the walls above the type cabinets.)

FOR THE LOVE OF LETTERPRESS My father and his brother (the original “Sargent Brothers”) took up the trade as teenagers in Fort Worth in the ‘20s, and while newspaper careers took them both away from printing for many years, my dad got back into the trade when I was 12 years old. He purchased a Kelsey outfit with which he taught the craft to me and to my brother. Three years later, he brought the C&P 10×15 Old Series job press of his boyhood back home, and that is still the press I use today.

DESIGNED TO PRINT I enjoy designing printing, especially if it’s with metal type, but for almost all my commercial jobs I defer to the excellent creative efforts of the several graphic designers with whom I work.

FULL TIME Since my schedule is my own these days, I guess one could say that printing is not only full-time, but 24-7, since I can take care of a client’s needs whenever fits their schedule. It’s been thus since I left regular syndicated cartooning a year or so ago, freeing me up to devote more time to the trade.

PRINTING FEATS I see that as the goal, however imperfectly achieved, of every job we do, to give the customer something we’re proud to stand behind. Still, there are certainly some pieces we’ve done over the years that do stand out, and I have a particularly fond regard for the various little handset books we’ve published (including two editions of our specimen book, and a brief history of the platen job press, published to commemorate the centennial of my press back in 2005).

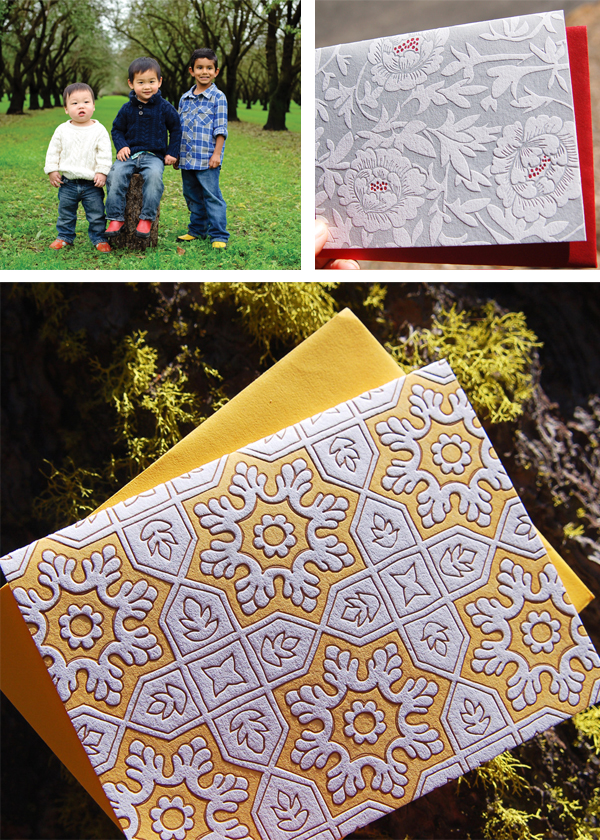

BOXCAR’S ROLE Oh, goodness, since almost all my commercial jobs are printed with Boxcar plates, it’s fair to say Boxcar is the sine qua non of our business. The plates themselves are always flawless, of course, and the service always timely, but by far the best part is the personal touch by which the staff, particularly Rebecca Miller, are always available and cheerfully willing to help us through the occasional digital-file nightmare, etc. I know you must have other customers, but I am always made to feel like Boxcar is there just waiting to meet Sargent Brothers’ needs. Thanks!

FIRST PRESS I learned the fundamentals on a Kelsey 5×8 Excelsior.

SHOP TIPS I think every printer, particularly one such as I who mostly works by himself, probably comes up over the years with dozens of tricks and techniques as he puzzles his way out of particular problems and situations, until they become just part of the craft, and he forgets they were once experimental innovations.

I can think of a few we’ve come up with, and they are probably worth some separate blog entries, so I’ll just cite one we’ve been having some luck with lately. Everybody who uses one of the older platen jobbers such as ours knows that the relatively unsophisticated inking system sometimes requires a little ingenuity in the case of relatively broad inked images. (Not big, huge color floods….with those I have learned the wise adage of one of my colleagues that “in letterpress, sometimes it’s okay just to say no.”). But for reasonable-sized bold areas, I’ve found they can be conquered with a couple of drops of something like Smooth Lith in the ink mix, and with providing a soft place for the impression to land, either by putting a couple of sheets of newsprint between tympan and pressboard, or even pasting some newsprint directly on the tympan (particularly if one is just trying to cover some limited areas). Also helps to “skip-feed” the pieces, so the ink has a little extra time to recover between impressions, and in some cases to go to the trouble of making the design into two press runs, one for the bold areas and one for the finer images. And I’m always receptive to anyone else’s ideas for this conundrum!

WHAT’S NEXT Job work has reached a fairly steady and comfortable level over here, and we look forward to getting the word about our offerings further out by word-of-mouth and our website. I’ve also had the privilege of working with a few young newcomers to the trade, and hope to continue in that way to keep letterpress thriving and growing.

A mighty round of thanks go out to Ben of Sargent Brothers Printers & Typographers for letting us take another peek into his sublime printing paradise.