Armed with sharpies, inks, and a dazzling inspiration, Katie Daniels of Concrete Lace is a phenomenal front to shaping the way letterpress has been deftly handling those warm wishes and special greetings to friend and family alike, be it a an eye-popping invitation or a special run edition card. A Georgia native, Katie’s been imbibing the wonderfully sweet fruits of the creative process.

If you’re in the Asheville, North Carolina area between August 2nd-5th, you should pop in to the Ladies of Letterpress Conference and say a big hello to Katie, as she’ll be rousing up some fun at the printer’s fair!

IT’S ALL IN THE CARDS I am originally from Foley, Alabama, on the Gulf Coast of Alabama (a sleepy town that didn’t know what to do with a rebellious punk vegan in the early 90’s). My mother is very creative, always had art supplies around and is no doubt the reason why I am an artist today. As a four-year-old, she encouraged me to start selling my handmade cards annually at the Foley “Art In The Park”event. 30 years later, after moving to Atlanta, the card making tradition continues under the name my awesome sister, Carla Kaiser, came up with: Concrete Lace. I also love history, collecting, cooking, exploring, gardening, animals and being a nerd.

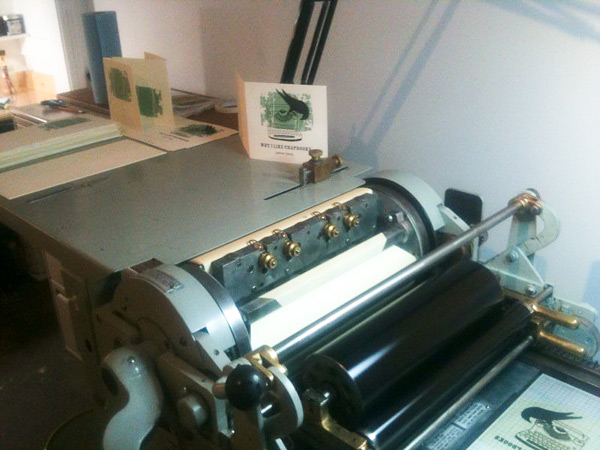

LETTERPRESS FOR LIFE I had dabbled in printmaking in the past, but when I got engaged in 2008, I really wanted to print my own invitations. A friend of mine told me about a local company, Praxium Press, who let you rent their press. The owner, Berwyn, was an awesome guy who introduced me to the Vandercook world. I loved it and immediately started designing & printing letterpress greeting cards and Atlanta neighborhood postcards, and was printing there so often that he convinced me it was time to get my own press. My awesome husband, Paul, then decided to set me up with a Vandercook studio in our home where Concrete Lace is thriving today.

GIFTED IN GEORGIA My studio is in my home, with the Vandercook & Kelsey upstairs in the small 7×10″ studio, and the Kluge, C&P and large format Challenge cutter down in the one-car garage. My upstairs studio is an inspirational eclectic mess, and the garage is more industrial feeling. I love to crank up local tunes super loud when I am printing, and I like to let the music set the tone for my productivity.

LIFE LESSONS + PRINTING MENTORS I had a fortunate job at one of the best health food stores, Brighter Day in Savannah, Georgia, while in college. I worked there for many years, and befriended a dear woman who also worked there, the late Joan Cobitz. Joan was among the first female MFA printmaking graduates of her time. She served as a major inspiration to me, as we traded house cleaning expeditions for printmaking classes in her home studio (printmaking was not offered at SCAD at the time). She was a great story teller and mentor for me and I think of her daily, not only in the press room, but also when I use her culinary advice or her prized Sabatier kitchen knife.

After graduating, I moved to Atlanta, and was fortunate enough to buy a house next door to a fourth generation letterpress printer, David Brough. He was a kind and generous man who loved his presses and loved to share information. Through David’s passing, I met another printer, Kevin O’Neil, who serves as my primary letterpress mentor today. Kevin very generously donated a beautiful C&P and Kluge to my pressroom, along with his invaluable information, which I will cherish forever.

DAILY GRIND For illustrations and hand lettering, I start out either with sharpies or pen and ink, then scan them in and convert them to vector graphics in Illustrator. Some illustrations are done directly on the computer in Illustrator (sometimes Photoshop then Illustrator), but I do all of my layouts, typesetting and separations in InDesign. My designing system is different for each line of cards as I like to switch things up so that I am always exploring new things. For example, I did a great deal of research on tapestries, pottery, wall paintings and other historic references when coming up with designs for my Greek and Hebrew lines, but did more hand lettering and illustration for my pet sitter cards, and illustration & typesetting for my French and German series.

THE DESIGNER IN THE PRINTER I am a professionally trained graphic designer, as well as a printer.

FULL TIME FUN I am a full time designer and a “part time” printer (but more like a 2nd full time job). I will never stop designing, so it is not my goal to give that up. I love it too much!

A LUCKY FIND I looked a year for a Vandercook SP15 or #4 (the only two sizes that would fit in my tiny upstairs studio), but no luck until I got Steve Robinson involved. He found me a #4 from an ink testing studio, and the press was in beautiful condition, with minimal miles logged and only one owner!

A VARIETY OF ACCOMPLISHMENTS I have won the Redbull Flugtag competition twice, thousands of dollars in numerous halloween costume contests, fostered and placed over 30 dogs, donated eggs twice, taught myself how to proficiently speak German in three years, forgot how to speak German in three months, taught myself how to play the accordion, started piano lessons at age 23, started tap lessons at age 31, won several design awards for work done for Emmy awards packaging and work created for television networks TNT, TBS and Turner Classic Movies, and most importantly, started Concrete Lace.

BOXCAR’S ROLE Boxcar sold me my base for my Vandercook and my Kelsey press, and I have been ordering my plates from Boxcar ever since. I really do find value in the relationships I have established with Boxcar, and feel that they have set a high industry standard, and high expectations, for customer service and plate making. They are fast and their site is user-friendly — key reasons for why I use them.

SHOP TIPS Don’t be discouraged. 1) This industry is all about exploring and learning, so I feel like even the biggest mistakes are the best teachers. 2) These machines were around WAY before any of us, and WAY before computers. We sometimes need to back off and not put pressure on ourselves to meet today’s standards of timing. These machines are much more powerful than we are, so it’s so important to think clearly and work at a pace that is comfortable for each of us individually.

WHAT’S NEXT I am working on an Italian line, and have two more lines in the works that will have to be a surprise… They probably won’t be ready until 2013, at this rate!

Big round of thanks out to Katie for letting us take a peek around the shop at Concrete Lace! Don’t forget to say “Hi!” to her at the Ladies of Letterpress Conference on August 2nd-5th, 2012!

THE PRESSES: I have four – A 10 x 15 Heidelberg Windmill, a 8 x 12 New Style C&P, a Vandercook 14 proof press and a 3 x 5 Kelsey that I use for demos at shows.

THE PRESSES: I have four – A 10 x 15 Heidelberg Windmill, a 8 x 12 New Style C&P, a Vandercook 14 proof press and a 3 x 5 Kelsey that I use for demos at shows.

When I’m not on the press, I’m usually sewing, drawing, and doing collage/ assemblage work. If I have access, I love to make paper. When I’m not engaged in some form of art, my favorite thing to do is pal around with my dog, Mr. Pants.

When I’m not on the press, I’m usually sewing, drawing, and doing collage/ assemblage work. If I have access, I love to make paper. When I’m not engaged in some form of art, my favorite thing to do is pal around with my dog, Mr. Pants.

Now I have a downtown location that has an alley entrance and is big enough to house me, my dog, Mr. Pants, a C&P craftsman, a huge guillotine, paper cutter and all my paper. We have been here going on 2 years now, and I am constantly humbled with how lucky I’ve been to be surrounded by such a great printing, bookbinding, & crafty community.

Now I have a downtown location that has an alley entrance and is big enough to house me, my dog, Mr. Pants, a C&P craftsman, a huge guillotine, paper cutter and all my paper. We have been here going on 2 years now, and I am constantly humbled with how lucky I’ve been to be surrounded by such a great printing, bookbinding, & crafty community. PRINTING FEATS Opening up this business is probably one of my biggest accomplishments. I have to learn all sorts of things that I never thought I would. My latest accomplishment, which I am very excited about, is that I was accepted into the MFA program at the University of Iowa Center for the Book and will be starting this fall.

PRINTING FEATS Opening up this business is probably one of my biggest accomplishments. I have to learn all sorts of things that I never thought I would. My latest accomplishment, which I am very excited about, is that I was accepted into the MFA program at the University of Iowa Center for the Book and will be starting this fall. BOXCAR’S ROLE Boxcar has been awesome! It is nice not worrying about making plates. It’s so convenient to be able to send out a digital file and get plates back that are so clean. If it weren’t for Boxcar, I would have more steps and be spending more time making them myself.

BOXCAR’S ROLE Boxcar has been awesome! It is nice not worrying about making plates. It’s so convenient to be able to send out a digital file and get plates back that are so clean. If it weren’t for Boxcar, I would have more steps and be spending more time making them myself. It’s such an advantage to be able to call Boxcar and get advice on how to make a file better for plates. I also think their printing videos are great. I feel like they really walked me through a number of printing issues.

It’s such an advantage to be able to call Boxcar and get advice on how to make a file better for plates. I also think their printing videos are great. I feel like they really walked me through a number of printing issues.

WHAT’S NEXT Well I’m lucky enough to have my sister, Katie Munger, back in Iowa. She has similar interests and recently decided to come back here and help me with the Paper Nest. I’m also really looking forward to getting a better handle on the business end of things and expanding. I’m hoping to offer more preprinted products as well as custom work and binding workshops. Eventually, I’d like to be able to offer equipment rental and printing workshops.

WHAT’S NEXT Well I’m lucky enough to have my sister, Katie Munger, back in Iowa. She has similar interests and recently decided to come back here and help me with the Paper Nest. I’m also really looking forward to getting a better handle on the business end of things and expanding. I’m hoping to offer more preprinted products as well as custom work and binding workshops. Eventually, I’d like to be able to offer equipment rental and printing workshops.

UP CLOSE WITH GUY PETTIT I love doberge cake from Gambino’s Bakery in New Orleans, Louisiana. That’s where a lot of my family is from. Doberge has about a thousand layers of dessert pudding alternating with white cake. I’m about to eat a piece. It’s really all that matters.

UP CLOSE WITH GUY PETTIT I love doberge cake from Gambino’s Bakery in New Orleans, Louisiana. That’s where a lot of my family is from. Doberge has about a thousand layers of dessert pudding alternating with white cake. I’m about to eat a piece. It’s really all that matters. BRILLIANCE IN THE BAY STATE We’re located in an old volunteer firehouse on a historic common (aka a 17th century palisade – the biggest one of its kind) in Hadley, next to the Connecticut river. I’ve had to do a lot of renovations but the space keeps opening itself up in really exciting ways, almost as though it was the natural next step in this buildings career. There’s a belfry. The concrete floors were perfect for the heavy machinery. Oh, and we have a shower in the studio! And great stone terrace out front. It’s a beautiful space.

BRILLIANCE IN THE BAY STATE We’re located in an old volunteer firehouse on a historic common (aka a 17th century palisade – the biggest one of its kind) in Hadley, next to the Connecticut river. I’ve had to do a lot of renovations but the space keeps opening itself up in really exciting ways, almost as though it was the natural next step in this buildings career. There’s a belfry. The concrete floors were perfect for the heavy machinery. Oh, and we have a shower in the studio! And great stone terrace out front. It’s a beautiful space.

PRESS HISTORY After my year with the borrowed Kelsey, which I’d probably consider my very first press, I bought a Vandercook 4T. It was a big jump but I knew that it was a press I could share with a lot of people and was really the cornerstone behind opening

PRESS HISTORY After my year with the borrowed Kelsey, which I’d probably consider my very first press, I bought a Vandercook 4T. It was a big jump but I knew that it was a press I could share with a lot of people and was really the cornerstone behind opening