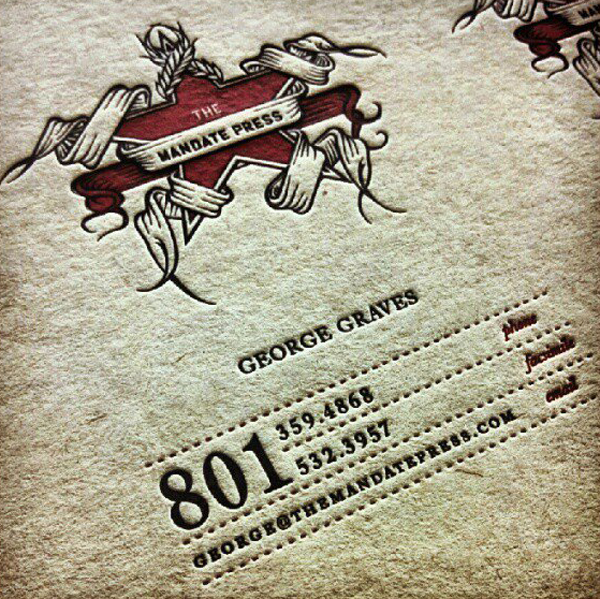

Today George Graves of The Mandate Press gives us a look at how the beginnings in hand-processing plates to running automatic presses (and the joys and headscratchers that go with it) gave him a sharp eye, a cool sense of printing logic, and a overflowing passion for all that is letterpress. We sat down with George to go over the finer details of press work, polishing opinions of modern letterpress, and of course the cool happenings of the AIGA Salt Lake City.

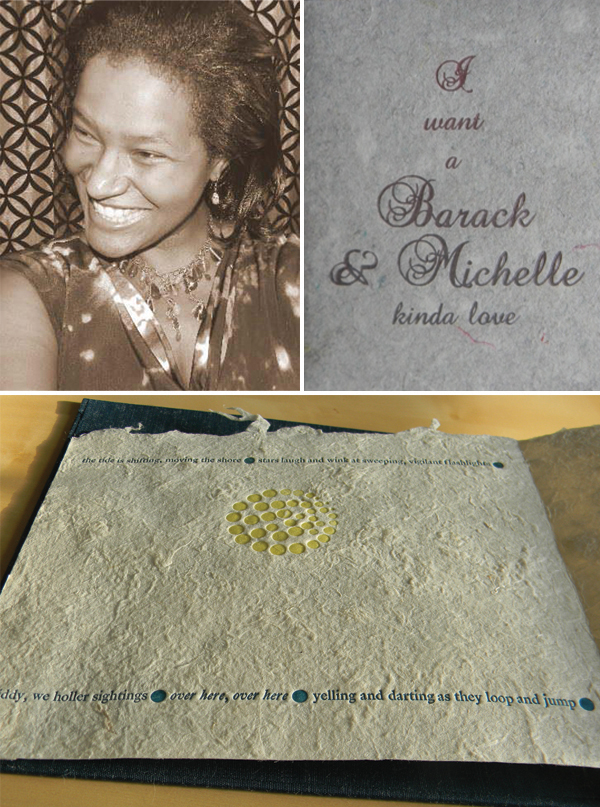

(left photograph courtesy of Angela Klempner)

EAST MEETS WEST I’m an East Coast boy with Maine roots, some Boston blood, and a passion for craft and quality.

LOVE AT FIRST SIGHT My faculty advisor and typography professor, Cynthia Roberts, first introduced me to letterpress after recognizing my appreciation for handwork. This was during my first or second year in the design program at Endicott College. It wasn’t until the second semester of my senior year that I was able to get my first taste of printing thanks to an introductory course at another school across town: Montserrat College of Art.

I spent my time in that course learning the basics of hand setting type and operating a treadle-powered C&P and a Vandercook SP-15. My first real exposure to photopolymer plates came when I printed a nine piece series of two-color posters for my senior thesis at Endicott. Limited by a college student’s budget, a tight schedule, and the need to hand-process each plate, that project taught me the finer points of imperfections and “happy accidents”.

In the spring of 2011, I was offered a 90-day internship at The Mandate Press in Salt Lake City, Utah. It would be a nearly 3,000 mile cross-country trek, in a 20-year-old Volvo. I couldn’t remember ever being further west than New York, but it was also the one gig that I had told myself I would move anywhere for. My moment of truth had arrived.

I started at Mandate in late June, it had been a year since the last time I had cranked a press, and I quickly realized just how little I knew. After I had reacquainted myself with the Vandercooks, I stepped up to our automatic presses.

Expecting to have some aversions to printing other designers’ work rather than my own, it was somewhere in the process of learning to operate the automatic presses that I realized the design and printing of a project were equally important pieces. My confirmation that this is what I want to do with my life came from making that discovery for myself and finding an intense pride in the trade I have chosen and the work I do each day.

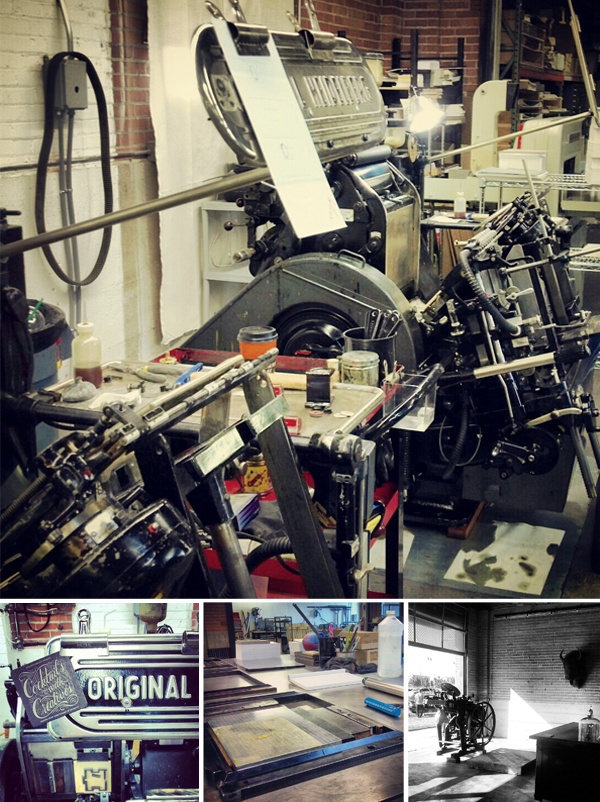

BRILLIANCE IN THE BEEHIVE STATE The Mandate Press is 10 blocks south of downtown SLC in a brick and mortar building on Main Street. The shop is just under 8,000 square feet and split between front and back. The front end of the shop serves as a gallery space, storefront, and our “office” space while the production all happens in the back. We have two glass garage doors in the front with a treadle powered platen press (a Chandler and Price and a Challenge Gordon) sitting just inside each one. While we run almost every job on automatic presses, we do run some lower quantity jobs on one of our Vandercook 4s in the front end of the shop. We actually have two 4s but one is in the middle of a rebuild.

Besides the four presses in the front of the shop, we have five automatic presses in the back. Two Heidelberg Windmills, Two Heidelberg Cylinders and a Frontex Automatic Cylinder. All built in the 50s or 60s, our lineup of automatics each has different muscles to flex. While the windmills are our workhorses and we have them cranking all day every day, our cylinders allow us to do larger work, heavier floods, and deeper impressions. The more comfortable I get with each press as I learn it, the more I appreciate the variety of abilities and each press becomes another tool in the shed or weapon in the arsenal.

As cheesy as it might sound, my favorite part of the shop is literally just being a part of it. From being a part of the planning that went into the show now hanging in our gallery, to learning the ins and outs and quirks of each press, to clearing room in the back of the shop so that we could drop our newest press into place with a forklift, each day at the shop reaffirms my desire to be a part of it. Especially considering my own doubts and the doubts that others had about my ability to make my letterpress goals a reality.

PRINTING MENTORS I owe every part of my daily routine to Ben Webster – owner, bossman and original pressman of The Mandate Press. He taught me the in’s and out’s for routine setups, he has patiently helped me develop the skill set necessary to solve new problems as they arise, and we are constantly discussing and polishing our opinions about the finer points of modern letterpress.

One of my biggest motivations at Mandate is a desire to repay Ben for the chance he took on an East Coast Luddite after a single Skype interview. I don’t think I’ll ever be sure if our chat really went that well or if he just wanted better access to fresh New England seafood.

Although Ben is the most obvious mentor of mine, I can’t forget the people that encouraged me to consider this path in the first place. Without the support of a core group of my professors at Endicott College (Specifically: Cynthia Roberts, Sanford Farrier, Larry Volk and Barbara Burgess-Maier), I may have never seen my current career path as a realistic option. Without Sarah Hulsey’s course at Montserrat College of Art, I might still be itching to try my hand at printing. And, although it was never a “mentorship” of any sort, without a heads-up from Mike Dacey of Repeat Press in Somerville, Massachusetts, I wouldn’t have known about the internship at Mandate. I will always be thankful for the role each of these people have played in allowing me to connect the dots on my path.

DESIGNER IN THE PRINTER As the Lead Printer at The Mandate Press, I don’t currently have the bandwidth to do any design for the shop but I try to stay active in design outside of Mandate. In June, I joined the board of AIGA Salt Lake City as Membership Director. Just recently, I designed a piece for a gallery show at the shop, and each year, I try to design a piece as a thank-you for those who support my Movember efforts.

THE CREATIVE PROCESS In a word: inefficient. I run in circles with too many different ideas and too many different sketches that get scanned and tweaked and printed and altered and scanned and tweaked etc, etc, etc… Until the final piece comes together during the last 5-10% of the process. Maybe one of these days I’ll streamline my design process but, for now, I’m content to focus my efforts on my performance in the pressroom.

PRESS HISTORY My first press is an 1880s Kelsey Excselsior tabletop press. When I started working with letterpress, it came to light that Red, a friend of my grandfather, had the press just sitting in his basement collecting dust. Not sure what Red wanted for the press, my dad and I went ahead and made plans to go get it. Red had inherited the press from his father, an old union printer who did some hobby printing at home, and it turned out that he was happy just to see the press go to a happy home. What I didn’t realize was that our haul included six cigar boxes of wooden type, a couple drawers of printer’s cuts and a small cabinet of lead type. After paying in handshakes and friendly banter, we headed home with the van riding low.

A trip to John Barrett’s Letterpress Things in Chicopee, Massachusetts quickly rounded out my small shop with a Hamilton cabinet, composing stone, and a few other odds and ends. I barely got things set up at home in Maine before heading to Salt Lake City so the press is in my dad’s custody now and he has been patiently tracking down rollers to fit the press. The press is old enough and the dimensions are odd enough that he has been sent two sets of misfit rollers and is waiting on the third round now.

PRINTING FEATS My number one point of pride is simply the fact that I packed up and moved across the country on the off-chance that I might hack it as a letterpress printer. Making that choice and now seeing the progress I have made as a printer is extremely gratifying.

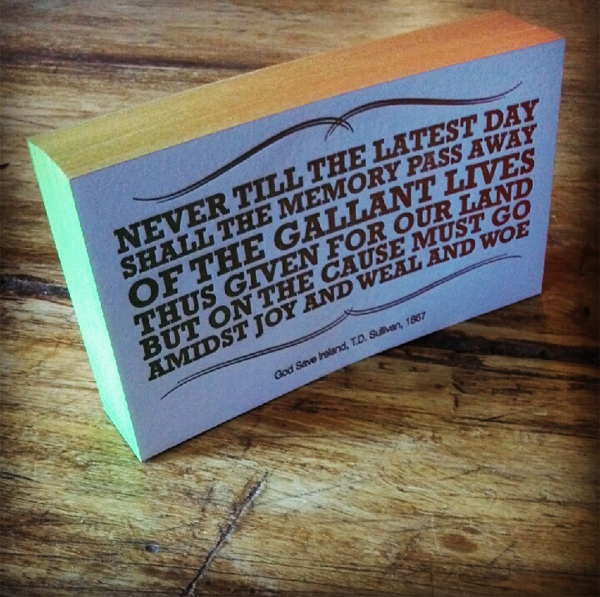

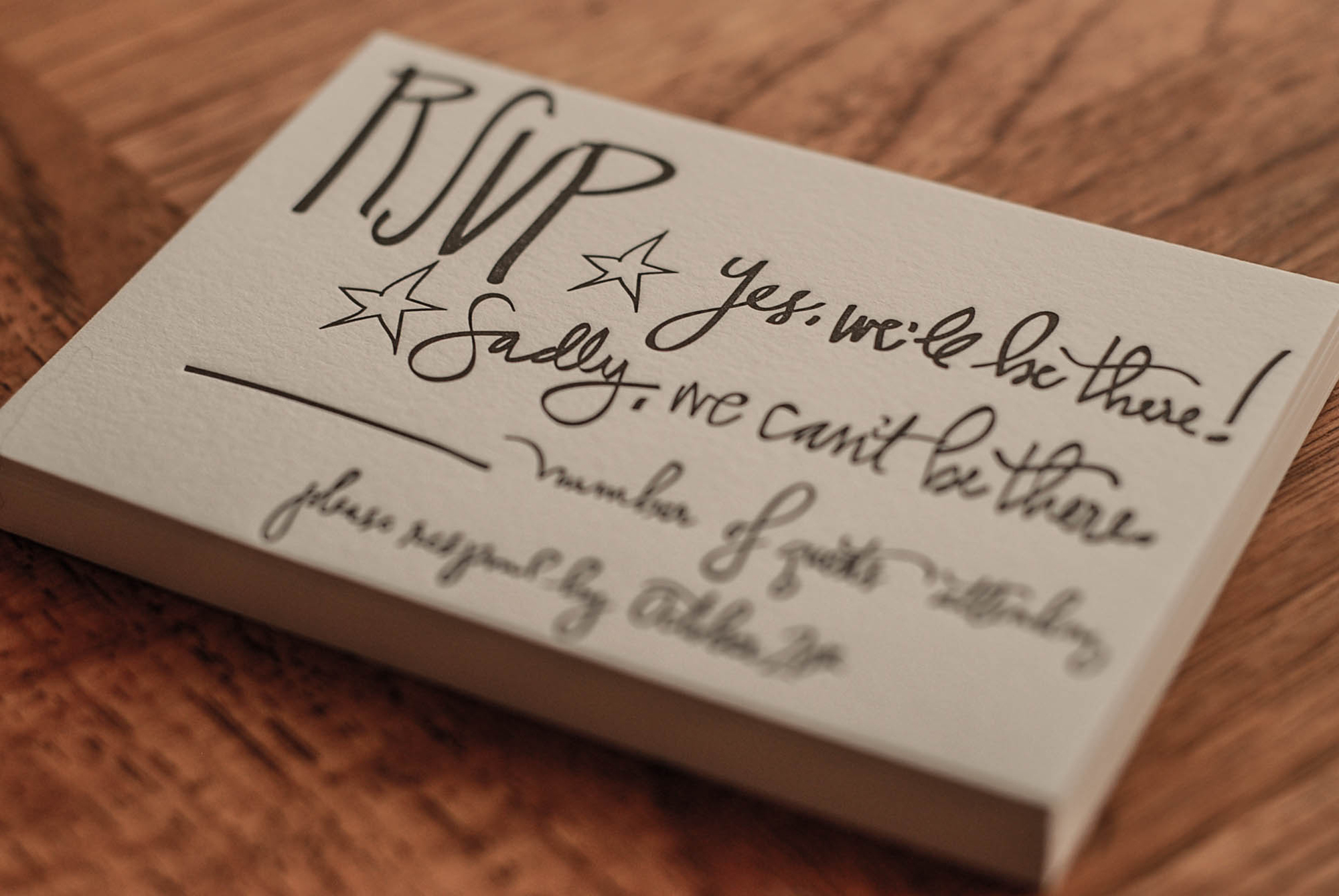

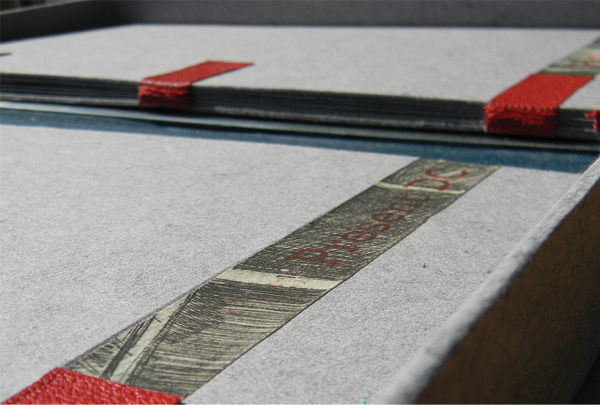

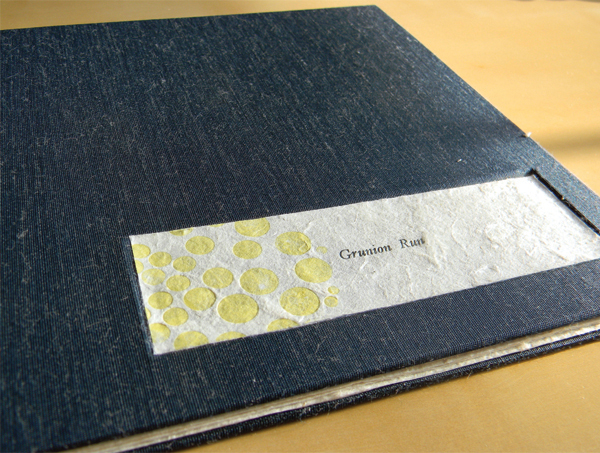

From less of a selfish standpoint, my biggest point of pride would have to be the show currently hanging in our gallery space at The Mandate Press. We have held a variety of events in our space but this was our first curated, letterpress specific show. We asked 21 artists to create a 2-color piece (Red 032 and Cool Grey 6) within the theme of “The Ghost in the Machine”, which we then printed in-house. The variety of interpretations and styles were held together by the consistency of paper, color, and the loose theme. Being involved in every aspect of the show from the early planning stages, to printing promotional materials, to final set up for the show made the opening night feel like that much more of a success. The prints from that show are still available for purchase from our Big Cartel store or in our Salt Lake City storefront.

BOXCAR’S ROLE Although we do have an assortment of type – both wood and lead – and printer’s cuts at Mandate, we use photopolymer plates for all of our client work. I hate to place those plates on anything but a Boxcar Base. In a commercial shop, where we pride ourselves not only on the quality of our work but also on our efficiency, the Boxcar Bases are one of the most useful tools in the shop because of their grid. When running two or more colors on a job, the grid allows me to quickly drop the next plate into place even if I’m running that plate on a different press.

SHOP TIPS “Slow is smooth and smooth is fast” ~ Phil Dunphy, Modern Family

Ben will quote this here and there around the shop and although its source is amusing, the point made is incredibly relevant. With the quantity of work that we see come through the doors at The Mandate Press, it could be easy to become focused on the timeline of each job and just push things through the shop. By slowing down and taking our time with each setup, or any process around the shop for that matter, the jobs run more smoothly, curveballs are eliminated, and things actually get done more quickly.

WHAT’S NEXT We are just now catching our collective breath from the efforts put into The Ghost in the Machine as well as a heavy shop involvement in AIGA SLC’s second Design Week. Jim Sheridan of Hatch Show Print visited SLC in early December to give a lecture and used our space to do a workshop as well. Hatch was one of the first shops I was exposed to when I first became interested in letterpress and getting a chance to meet Jim and work with him is an opportunity I never really expected to have.

Big round of thanks to George for letting us take a sneak peek at The Mandate Press!

THE PRESSES In general use we have seven presses. There is the C&P treadle press that came from the American Typefounders Company; two C&P Craftsman presses (one for printing and one for scoring and perfing); a Windmill for longer jobs; a Heidlberg KSB; and finally two Vandercooks, a Universal III for poster work, when we get it, and an SP20 that we use almost exclusively for proofing type. In addition to that we have a number of random presses in various states of repair, mostly small format platen presses that no one seems to want these days.

THE PRESSES In general use we have seven presses. There is the C&P treadle press that came from the American Typefounders Company; two C&P Craftsman presses (one for printing and one for scoring and perfing); a Windmill for longer jobs; a Heidlberg KSB; and finally two Vandercooks, a Universal III for poster work, when we get it, and an SP20 that we use almost exclusively for proofing type. In addition to that we have a number of random presses in various states of repair, mostly small format platen presses that no one seems to want these days.