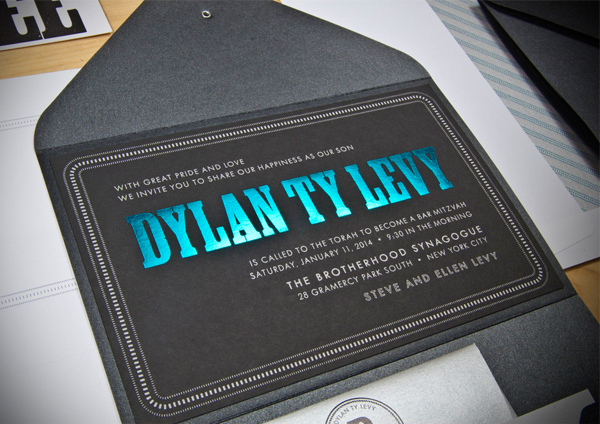

We followed Fabiano Santos of Pergam Press into his inking abode settled in the breathtaking city of Carapicuiba, Brazil. Opening the doors to his shop for us, Fabiano let us tour his cozy shop as well as exemplifying the care and technique one acquires when a Heidelberg is present.

THE PRESSES We have two presses, a Heidelberg Windmill and a Minerva Catu, which is completely manufactured in Brazil. Our first acquisition was Catu, here in Brazil it is called Catuzinha. It belonged to a printer man for many years and when he was retired he kept it in his garage. He was very careful man and the press was kept in a very good way. One day, my wife Cris saw an internet ad about the Heidelberg. It was at a company and was used just to put numbers, even so it had a beautiful story because the press belonged to the owner of the company who left it to his son.

SIZE OF PRINT SHOP Our workplace size is 30 square meters. It is my parents garage and the place was a wallpaper warehouse. We made a big effort to take away all those wallpapers and nowadays we use some to cover the presses or as a carpet.

TYPE OF SHOP Commercial.

LOCATION We are at grande SP outskirts, a city called Carapicuiba, where I have always lived with my parents. It is an ordinary neighborhood, with nice people, good neighbors, like country-side where everybody knows each other. People who live here always ask me about what my business is and they get amazed at how the presses work. Around us there are not so many skyscrapers or many cars. It is a very calm way of life. There is no traffic, just small industries and we can feel the fresh air which is something rare in a big city like SP. Further, we want to contribute to help people who live here, it is a special place to us.

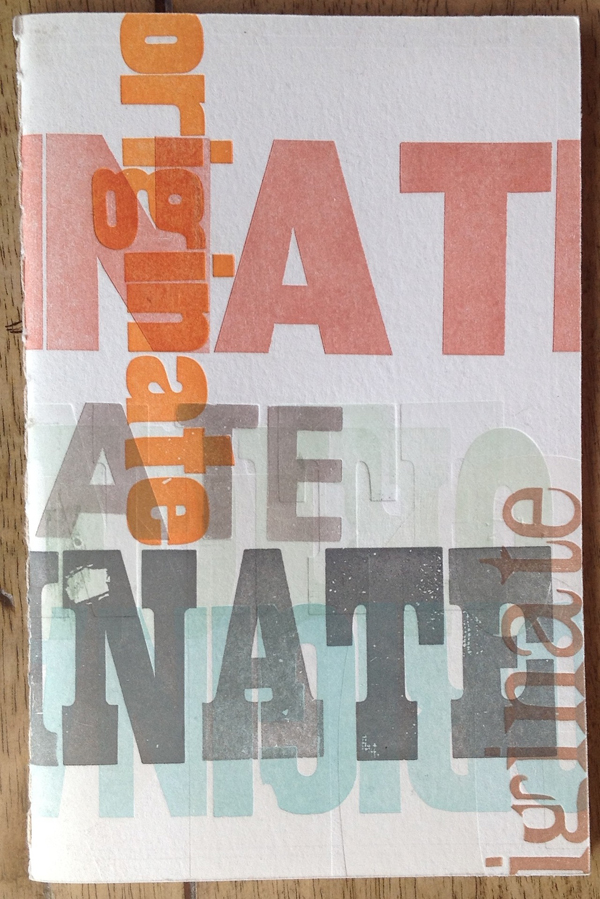

FAVORITE THING ABOUT THE SHOP I like to arrive early in the morning, open the doors and feel the typical Pergam Press smell. It is a mix of paper and ink that makes the place unique and allows me to say “Wow! I’m at Pergam Press”. We have a bookshelf full of books and antique toys and also many vinyl Long Plays. But our favorite thing is the antique clichés from the 70’s and 80’s that we found out in the garbage of an old company and today they are here at Pergam Press and we love them!

NUMBER OF PRINTERS IN SPACE We have two printers.

MOST VALUABLE SHOP TOOL I believe the most valuable tool is the Boxcar Base. It is really important to us because it improved the quality of our prints.

INK OF CHOICE We use ink from an antique factory called Tradição Bremensis made in Brazil. Nowadays, we are in love with yellow.

SOLVENT OF CHOICE The clean-up used to be the slow step of the process since we are very careful about the presses. Usually we use Kerosene but we are searching for eco-friendly products to do the clean up.

PLATE AND BASE OF CHOICE We always use the Boxcar Base and Photopolymer KF95 plates.

OIL OF CHOICE We use Petrobras motor oil.

WHAT TYPE OF RAGS DO YOU CLEAN UP YOUR PRESSES WITH The good and old cotton shirt is irreplaceable. Some friends always donate to us.

FLOORING MATERIAL Our floor is made of concrete covered with ceramic.

FLOOR PLAN TIPS We appreciate the natural way of concrete.

PIED TYPE No.

ORGANIZATION ADVICE Always keep the inks very well identified & we also make more than we need in case of reprints.

PRINTING ADVICE It took a long time to find out how important it is to have the correct height of the rollers and the ink volume. At the beginning, we put a huge amount of ink and today we deal it as a chef deals with the ingredients to prepare a dish: with just the right amount.

We are young and have so much to learn about letterpress but everyday is a new experience, a new discovery.

Many thanks to Fabiano for giving us a tour inside of Pergam Press!